Dire

ctors' message:

We hope you have been enjoying the onset of Spring! We've had a busy few months preparing for the NSF review of the MRSEC (end of April) and are in the final stages of preparation. News worthy items include a new assistant for the MRSEC, Jennifer Weber (more details below), Engineering Expo on campus, the WISYS meeting in July in River Falls, the Regional Materials and Manufacturing Network (RM2N) kick off meeting in September 21-22 at UW Eau Claire, as well as a new Director of the Grainger Institute (see below).

Adapt and thrive! (by Rick Berg)

http://issuu.com/newnorthb2b/docs/march_2015/1

"Innovation is a survival tactic for northeast wisconsin manufacturers"

We were inspired by this article found the B2b magazine New North B2B.

Materials science is one of the fundamental doorways to new innovations

understanding the science behind how and why materials behave the way they do allows new design and process rules for optimized properties and a better product. The iterative process involves materials characterization at the heart of the discovery process. Asking the right questions and taking measurements at the relevant scale is critical; and having the right tools and instruments that allow you to do this is a tremendous time saver. The characterization facilities and subject matter experts at the UW campuses allow these materials optimization processes to be done and in fact are already done every day by companies eager to build a better product and to gain that technological edge over their competition.

The first step is knowing your problem and that may not be a trivial question. Subject matter experts and consultants can help you get to the root or possible roots of your materials problem. The next step is figuring out what instruments can help you get more insight into the problem or to confirm your hypothesis. Again, subject matter experts can help you with this. Where do you find these materials and technological experts? Word of mouth is a good starting point, but this approach is also very linear and sequential. What would be nice is to get a short list of possible experts with a description fo their background and experience. This can be done by contacting us with some help from the WIsconsin Materials Institute (WMI) developed Regional Materials and Manufacturing Network (RM2N) - http://wiscmat.org

As always, if you have questions, suggestions or comments, please let us know!

Best regards,

Felix Lu and Erin Gill,

Co-Directors, UW AMIC

|

New Staff member - Jennifer Weber

Some of you may have received emails or calls from Jennifer recently. Jennifer Weber is the new Special Programs Coordinator for the Materials Research Science and Engineering Center (MRSEC) and has been working very closely with Erin Gill. Jennifer has a Bachelor's Degree in Communication from the University of Wisconsin - Milwaukee and worked in the supply chain at Kohler Company for five years, supporting the Director of Customer Service. Jennifer can be reached at [email protected].

|

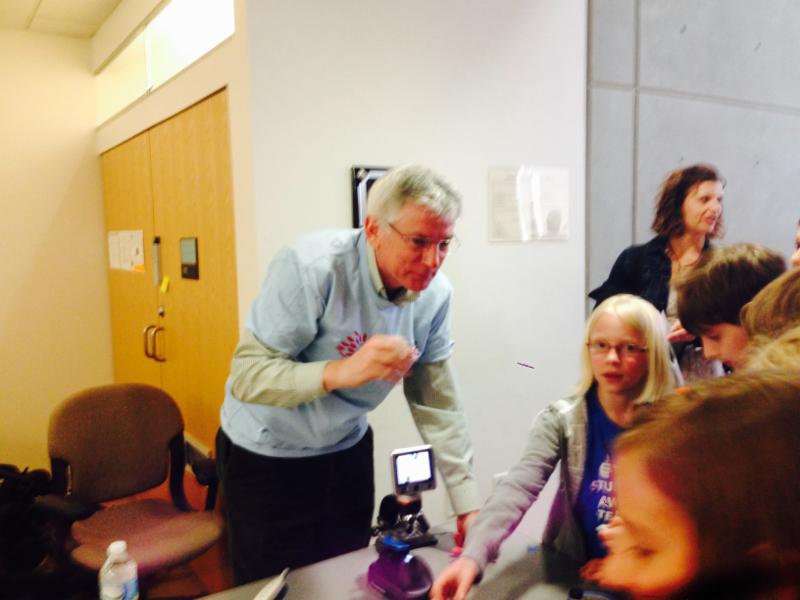

Engineering Expo was held on April 16-18 and was a great success with over 4000 visitors and heavy participation by MRSEC students, staff and faculty! Below are a few pictures of the event with Nick Abbott with the liquid crystal sensors, Sue Babcock on the tabletop SEM, and students Luke Rolling and Geethanjali Anand with the gold nanoparticle sensors.

|

|

|

| Dan Thoma is the director of the Grainger institute for Engineering at the University of Wisconsin-Madison. |

"The ages of human development are based on the materials peoples of the day used: the Stone Age, the Bronze Age, the Iron Age," says Dan Thoma, deputy division leader for the Los Alamos National Laboratory (LANL) Materials Science and Technology Division. "Technology is the driver. Materials are the enabler - so that discovery point is really what impacts society."

In June, Thoma will become the first director of the Grainger Institute for Engineering at the University of Wisconsin-Madison. Funded in 2014 with $25 million from The Grainger Foundation of Lake Forest, Illinois, the institute is an incubator for transdisciplinary research in the UW-Madison College of Engineering.

The institute's first focus areas - advanced manufacturing and accelerated materials discovery - center around the idea that new materials benefit everyone. These intertwined areas are critical to state and national manufacturers' economic competitiveness in a global marketplace. "A lot of advanced manufacturing now can be summarized as 'twice as fast; twice as cheap," says Thoma.

Thoma, who is an active leader in national and international materials societies, brings to the institute a particular passion for using scientific and engineering advances to solve challenges that affect society and human well-being. He has spent much of his professional life focused on developing teams of talented people. "In each case, I've been asked to build something new," he says. "I like that challenge."

Read More:

http://www.news.wisc.edu/23626?utm_source=iUW&utm_medium=email&utm_campaign=iUW2015-04-07

|

|

Recent patent filings from WARF and WYSIS

|

THE INVENTION

UW-Madison researchers have developed easier-to-cleave neutral layers using a new type of polymer film. Linkages both within the film, as well as between the film and its substrate, may be cleaved apart using only a mild acid or light ('photocleaving').

The film is made of random copolymer chains having crosslinkable functional groups. The film can be coated on a BCP substrate and then selectively removed.

APPLICATIONS

- Nanopatterning in the microelectronics industry

- Integrated circuits, display technology and media storage

- Degradable hydrogels and soft scaffolds

KEY BENEFITS

- Neutral layer can be readily removed.

- Avoids harsh techniques like reactive ion etching

- Does not disturb the underlying substrate or overlying template

- Cleavage occurs within minutes.

- Enables the use of materials such as graphene

THE INVENTION

UW-Madison researchers have developed a reaction system and method for the photoreduction of molecules that uses diamonds with a negative electron affinity as the photocatalyst. The method involves illuminating a fluid sample containing the molecules to be reduced and a hydrogen surface-terminated diamond having a negative electron affinity. The illuminating light wavelength induces the emission of electrons from the diamond directly into the fluid sample. These emitted electrons induce the reduction of the molecules, forming a reduction product. The product then can be separated from the fluid sample and collected. This method can be used to reduce a variety of molecules, including small molecules such as N2, CO2, CO or NOx and aromatic molecules that include one or more benzene rings.

APPLICATIONS

- Photocatalyst for the reduction of small molecules

- Ammonia production

KEY BENEFITS

- Hydrogen-coated diamond possesses higher photocatalytic activity and retains this activity for a longer period of time than existing catalysts.

- Diamond powder may be less expensive than Ru-impregnated TiO2.

- The energy level associated with this reaction is significantly lower than existing catalysts

(INVENTORS - John Perepezko)

THE INVENTION

UW-Madison researchers have developed alumina coatings that form protective, oxidation-resistant scales on ceramic substrates at high temperatures. The method for coating the ceramic-based substrates involves a two-stage deposition process. This process comprises depositing a layer of molybdenum metal onto a surface of the substrate and subsequently co-depositing silicon and boron onto the layer of molybdenum in the presence of alumina to form a continuous MoSiB coating. Ceramic-based substrates that can be coated in accordance with this method include ultra-high temperature ceramics, fiber-reinforced matrix composites and refractory metal cermets.

APPLICATIONS

- Jet engines

- Hypersonic vehicles

- Thermal electrodes

KEY BENEFITS

- Reduces or inhibits the formation of volatile species in the scales that form at high temperatures

- Reduces the rate at which oxygen diffuses through the scale

- Can provide protection from reactions involving the coating and sands

- Also can provide protection from sand infiltration into the coating

THE INVENTION

UW-Madison researchers have developed an improved method for generating oxygen and hydrogen with a cobalt-oxide electrocatalyst that uses fluorophosphate or a similar anion electrolyte as the electrolytic buffer in the electrolysis reaction. Using this method, an anode and a cathode are placed in an aqueous solution containing water, a cobalt cation and the anion electrolyte. Then an external source of energy (potentially derived from solar, wind or other renewable energy) drives the electrolysis reaction to generate oxygen and hydrogen. Alternatively, a catalyst containing cobalt, oxygen and the anion electrolyte can be deposited on the anode of the electrochemical cell prior to electrolysis in cobalt-free conditions.

This cobalt-oxide catalyst enables efficient oxidation of water at room temperature over a more favorable pH range. The reduction in overpotential makes it easier and less expensive to split water into hydrogen and oxygen, while the expanded pH range allows water oxidation to be coupled with desirable reactions such as reduction of carbon dioxide at the cathode. In addition, the electrolyte buffers are compatible with conventional materials used in electrochemical cells. The hydrogen gas output of this process can be collected and used as an alternative fuel source or as feedstock for conversion into other fuels or materials. The oxygen gas can be collected, dried and used for any process requiring pure oxygen.

APPLICATIONS

- Storage of renewable energy as hydrogen fuel

- Electrochemical synthetic reactions

KEY BENEFITS

- Enables oxidation of water over a broad pH range

- Allows use of electrochemical cells made of conventional materials

|

Fostering entrepreneurship at the UW-Madison: Executive Q&A|John Surdyk

When it co mes to entrepreneurship at the UW-Madison, John Surdyk is smack-dab in the middle of the action, right where the ideas start. mes to entrepreneurship at the UW-Madison, John Surdyk is smack-dab in the middle of the action, right where the ideas start.

Surdyk is director of INSITE, the Initiative for Studies in Transformational Entrepreneurship, a "knowledge center" in the School of Business set up to encourage and facilitate the art and science of starting a company.

A Thiensville native who grew up in Wisconsin, Florida and Hawaii, Surdyk got into the entrepreneur arena "by accident," he said.

After earning a degree in earth systems science at Stanford University, Surdyk got a job at Navigant Consulting, Chicago. His field was energy and high technology, and he worked with companies such as Enron (now defunct), El Paso Energy, and Pacific Gas & Electric Co., advising them in lawsuits involving environmental issues.

But the timing could have been better. In late 1999, after Surdyk had been there for two years, three top Navigant officials were forced out over questionable stock purchases.

A few months later, Surdyk went to see the movie "Erin Brockovich," about the environmental activist who launched a huge class action lawsuit against Pacific Gas & Electric for alleged drinking water contamination. It hit home: Navigant's West Coast office was representing PG&E.

|

|

Upcoming conferences & seminars

|

The Midwest Energy Research Consortium (M-WERC) coordinates research activities and advances technology innovation in the Energy, Power, and Controls (EPC) industry. M-WERC's member include manufacturers involved in the EPC industry, academic research organizations, technical colleges, and government agencies. Part of our mission is to organize and participate in events that build awareness of the achievements of M-WERC and its member companies and spread information on technology-related activities that aid our members in these sectors.

All attendees of the WMEP Manufacturing Matters! 2015 event will receive a 25% discount on a one year membership in M-WERC (good for membership through March 31, 2016), if you sign up before May 31, 2015.

See below for upcoming M-WERC events that you may be interested in participating in - including upcoming events focused on:

? Open Innovation - in early May the Energy Innovation Center will host a panel of speakers from M-WERC's academic research partners discuss their Energy Technology Innovation Systems programs at UW-Madison.

? Workforce Development - an event in May that will focus on the workforce development needs and careers pathways in the manufacturing and energy sectors.

? Smart Manufacturing - our July event, covering the emerging topics of advanced manufacturing and energy efficient manufacturing opportunities.

See below for more information on these upcoming events - and join M-WERC as a member so you can take full advantage of these and other M-WERC activities and member benefits.

BIO Legislative Day Fly-In 2015

4/14/2015 ? 4/15/2015

Wisconsin Stem Cell Symposium - Engineering Limb Regeneration

4/22/2015

International Forum on Consciousness

5/7/2015 ? 5/8/2015

6/15/2015 ? 6/18/2015

Location: Philadelphia, Pennsylvania

- 2015 MRS Spring Meeting & Exhibit

- April 6-10, 2015

- San Francisco, California

The 2015 MRS Spring Meeting and Exhibit will be held in San Francisco, California. All technical sessions and non-technical events will be held at the Moscone West Convention Center, San Francisco Marriott Marquis and The Westin San Francisco Market Street. Locations and schedules of individual symposia will be posted in early 2015 as available. Non-technical events will be listed on the menu to the left. Information about individual sessions and special events will be posted as they become available closer to the meeting.

|

Save the date (Sept 21-22, UW Eau Claire) - for the 2015 Regional Materials and Manufacturing Network (RM2N) Symposium!

Please join us for the

kick off meeting that brings together materials science colleagues, students from campus member affiliates, and industry representatives.

Program includes :

a student poster session,

networking opportunities,

research and industrial talks.

Discussions will include how the RM2N network can better engage Wisconsin industry/manufacturers and the UW system schools and put us in a better position to take advantage of local expertise, instrumentation and other resources, and how this can work to benefit all

parties.

|

High Bandwidth Spectroscopic Ellipsometer

The MRSEC is in the process of procuring a pair of spectroscopic ellipsometers with a combined spectral bandwidth from 200 nm to 30.0 microns.

Modern ellipsometers are complex instruments that incorporate a wide variety of radiation sources, detectors, digital electronics and software. The range of wavelength employed is far in excess of what is visible so strictly these are no longer optical instruments.

Single-wavelength vs. spectroscopic ellipsometry

Single-wavelength ellipsometry employs a monochromatic light source. This is usually a laser in the visible spectral region, for instance, a HeNe laser with a wavelength of 632.8 nm. Therefore, single-wavelength ellipsometry is also called laser ellipsometry. The advantage of laser ellipsometry is that laser beams can be focused on a small spot size. Furthermore, lasers have a higher power than broad band light sources. Therefore, laser ellipsometry can be used for imaging (see below). However, the experimental output is restricted to one set of and values per measurement. Spectroscopic ellipsometry (SE) employs broad band light sources, which cover a certain spectral range in the infrared, visible or ultraviolet spectral region. By that the complex refractive index or the dielectric function tensor in the corresponding spectral region can be obtained, which gives access to a large number of fundamental physical properties. Infrared spectroscopic ellipsometry (IRSE) can probe lattice vibrational (phonon) and free charge carrier (plasmon) properties. Spectroscopic ellipsometry in the near infrared, visible up to ultraviolet spectral region studies the refractive index in the transparency or below-band-gap region and electronic properties, for instance, band-to-band transitions or excitons.

[Source: Wikipedia]

Quartz Crystal Microbalance

The MRSEC is in the process of procuring a a QCM-D which will reside in the Soft Materials Laboratory in Engineering Hall.

A quartz crystal microbalance (QCM) measures a mass variation per unit area by measuring the change in

frequency

of a

quartz crystal

resonator. The

resonance

is disturbed by the addition or removal of a small mass due to oxide growth/decay or film deposition at the surface of the acoustic resonator. The QCM can be used under vacuum, in gas

phase

("gas sensor", first use described by King

[1]

) and more recently in liquid environments. It is useful for monitoring the rate of deposition in

thin film deposition

systems under vacuum. In liquid, it is highly effective at determining the

affinity

of molecules (

proteins

, in particular) to surfaces functionalized with recognition sites. Larger entities such as

viruses

or

polymers

are investigated, as well. QCM has also been used to investigate interactions between biomolecules. Frequency measurements are easily made to high precision (discussed below); hence, it is easy to measure mass densities down to a level of below 1 ?g/cm2. In addition to measuring the frequency, the

dissipation

factor (equivalent to the resonance bandwidth) is often measured to help analysis. The dissipation factor is the inverse quality factor of the resonance, Q?1 = w/fr (see below); it quantifies the

damping

in the system and is related to the sample's

viscoelastic

properties.

[Source: Wikipedia]

If you have any questions about these instruments, please contact Felix Lu (

[email protected]) or call me at (608) 262-6099.

|

The Fisher Barton Group, a company comprising ten global manufacturing subsidiaries, is expanding its Research and Development department with the addition of the newly incorporated Fisher Barton Technology Center. The new entity, located in Watertown, Wisconsin, just 40 miles east of the UW-Madison campus, will be used as a group-wide resource for R&D initiatives and materials innovation.

"The Technology Center allows us to build on our legacy of materials innovation and engineering expertise," said Igor Zelenovskiy, President of the Fisher Barton Technology Center. "This advancement in our capabilities creates a path for exciting new opportunities for Fisher Barton."

The Technology Center was established as a means to support Fisher Barton and its customers with an emphasis in three main areas: Metallurgical development, coating development, and process engineering.

The range of materials utilized at Fisher Barton has grown steadily throughout the past four decades. From medium and high-carbon steels, to carbides, ceramics, and more, the Tech Center positions Fisher Barton to better meet the ever changing demands of the market. Current projects include work with tungsten carbide, iron-based alloys and alumina-based dielectric coatings, servicing industries such as Agriculture, Medical, and Oil & Gas.

Thermal spraying, PTA welding, laser cladding, and diffusion coatings are among the key processes that will be employed at the Tech Center. The facility, which will officially open summer 2015, will also be equipped with state-of-the-art technology to optimize testing and analysis procedures.

Fisher Barton has positioned this new facility as the epicenter of expertise for the company, assigning key members of its leadership and engineering teams to drive success. The development of technical talent through the use of co-op programs and academic partnerships is a key component to the success plan.

Fisher Barton is a company with deep roots in technology and innovation. The recent investment in the new Technology Center is reflective of the company's recommitment and dedication to these fundamental concepts.

For more information, please visit www.fisher-barton.com/Fisher-Barton-Technology-Center.

Do you want to submit a member spotlight for your company? Please contact Felix Lu (

[email protected]) for more details.

|

Date/time: Monday, May 4, 2015, from 1 - 5 PM

Where: Wisconsin Institutes for Discovery,

Science Teaching Lab, Rm 2280B

University of Wisconsin

330 N Orchard St., Madison, WI

Overview:

Preparing biological and many materials specimens for

electron microscopy requires dozens of reagent exchanges for fixation, dehydration, embedding, and then more again for TEM grid staining or immuno-labeling. The process of delivering reagents, orienting specimens, and documenting each specimen and grid is tedious, inaccurate, inconsistent, and wasteful. Specimens and grids are easy to lose, mix-up

or damage during handling.

Isn't there a better way?

This workshop will provide hands-on laboratory instruction on the mPrep? System. The mPrep

System is a new family of labware designed for microscopy. It is compatible with existing labware,

adaptable, and efficient for processing and handling TEM and SEM specimens, TEM grids, and

many other types of specimens. The system enables easy, simultaneous and efficient preparation

of one or a dozen specimens or grids with much less effort than other methods, while reducing

reagent consumption to one-tenth of most other methods. The workshop will provide hands on

experience with mPrep specimen and grid preparation for academic and pharmaceutical research,

and for mixed research and clinical labs.

Applications:

- Animal and plant tissues and small organisms such as worms

- Viruses, bacteria, other microorganisms

- Immuno-labeling and other complex protocols

- Nanoparticles and other nano-materials

- Integrating mPrep into the cell culture lab including 3D culture

- Integrating mPrep into biomaterials and bioengineering

- Polymers, pharmaceutics, and other soft materials

There is no cost to attend, but registration is limited.

Please reserve your spot in this workshop soon.

RSVP no later than May 1 to [email protected]

Do you want to submit a member spotlight for your company? Please contact Felix Lu (

[email protected]) for more details.

|

|

UW Materials Science in the news

|

|

|

Chemistry Professor Mark Ediger

|

By figuring out how to precisely order the molecules that make up what scientists call organic glass - the materials at the heart of some electronic displays, light-emitting diodes and solar cells - a team of chemists from the University of Wisconsin-Madison has set the stage for more efficient and sturdier portable electronic devices and possibly a new generation of solar cells based on organic materials.

Writing this week (March 23, 2015) in the Proceedings of the National Academy of Sciences (PNAS), a team led by UW-Madison chemistry Professor Mark Ediger describes a method capable of routinely imposing order on organic glasses by enabling their production so that the molecules that make up the glasses are ideally positioned.

"Glasses are usually isotropic, meaning their properties are the same from any direction," explains Ediger, a world expert on glass, who conducted the study with UW-Madison researchers Shakeel Dalal and Diane Walters.

Glass, says Ediger, can be made from any number of materials. The most familiar, of course, is window glass, made primarily of the mineral silica. But other types of glass can be made of metal and other materials, and nature makes its own variants such as the volcanic glass obsidian. Organic glasses are made using materials based on carbon instead of silica.

The new organic glasses devised by Ediger's team "have the molecules oriented in specific ways, standing up or lying down," he explains. The orientation affects performance and can confer greater levels of efficiency and durability in the devices they are used in.

|

|

|

Food science graduate student Maya Warren is pictured in a research lab in Babcock Hall. When Warren completes her doctoral degree in August 2015, she aspires to launch a food consulting business and a TV show showcasing frozen desserts from around the world. Photos: Jeff Miller |

You may know Maya Warren for her $1 million victory, shared with fellow food science grad student Amy DeJong, in the latest edition of the CBS reality show "The Amazing Race." You likely do not know that, after she receives her Ph.D. from the University of Wisconsin-Madison in August, she intends to homogenize her TV experience with her knowledge of ice cream, outgoing nature, and self-confidence to develop a show showcasing frozen desserts around the world.

"Even before the race, I had this idea to do a television show on ice cream and frozen dessert," she says. "I've always been a person who is interested in doing something for the love, not the money."

Does ice cream seem lightweight? Perhaps, but the "Amazing Race" contestants who slighted her team as the "Candy Girls" got their comeuppance with the duo's come-from-behind victory in December's final episode.

Ice cream is the perfect communication vehicle, Warren says. "Talking to 5-year-olds, or 80-year-olds, it makes their eyes light up. The science is tangible. I can break it down so people can understand."

Her comparative advantage, aside from that easy, enthusiastic manner, rests squarely on her education at UW-Madison: the science of food, the subtle interaction between flavor, texture, and (in the case of ice cream) temperature and melting properties.

For her dissertation, Warren is exploring fat agglomeration - how fat molecules cluster together. Her work could help ice-cream makers produce low-fat ice cream with better "mouth feel" and less gum and binder.

|

A LOT of tosh is talked about "nanotechnology", much of it designed to separate unwary investors from their hard-earned cash. This does not mean, though, that controlling the structure of things at the level of nanometres (billionths of a metre) is unimportant. In materials science it is vital, as a paper just published in Nature, by Hansoo Kim and his colleagues at the Pohang University of Science and Technology, in South Korea, demonstrates. By manipulating the structure of steel on a nanometre scale, Dr Kim has produced a material which has the strength and the lightness of titanium alloys but will, when produced at scale, cost a tenth as much.

Steel is useful because it is strong and cheap. But it is also heavy. It has, therefore, always been useless for applications such as aircraft. In a world that demands the ever-more efficient use of fuel in motor cars and lorries, it is now falling out of favour there, too. According to Dr Kim, the share by weight of steel in an average light vehicle fell from 68.1% in 1995 to 60.1% in 2011.

Read more at:

http://www.economist.com/news/science-and-technology/21642107-alloy-iron-and-aluminium-good-titanium-tenth

|

|

|

| Samples show some of the colors researchers have produced in electrochromic polymers. The materials can be used for applications such as sunglasses and window tinting that can be turned on and off through the application of an electrical potential. Image: Rob Felt |

Artists, print designers and interior decorators have long had access to a broad palette of paint and ink colors for their work. Now, researchers have created a broad color palette of electrochromic polymers, materials that can be used for sunglasses, window tinting and other applications that rely on electrical current to produce color changes.

By developing electrochromic polymer materials in a range of primary and secondary colors and combining them in specific blends, the researchers have covered the color spectrum - even creating four shades of brown, a particularly difficult color combination. The materials could be used to make sunglasses that change from tinted to clear in a matter of seconds, at the press of a button. Other uses could include window tinting, signage and even greeting cards that change color through the application of low-voltage electrical current.

Supported by BASF, the research is reported in ACS Applied Materials & Interfaces. The research was done in the laboratory of John Reynolds, a professor in the School of Chemistry and Biochemisty and the School of Materials Science and Engineering at the Georgia Institute of Technology.

"We've demonstrated the ability to create virtually any color we want by mixing different electrochromic polymers, just like mixing paint," said Anna ?sterholm, a research scientist in Georgia Tech's School of Chemistry and Biochemistry and the paper's first author. "Using a simple coating method or even inkjet printing, we can create films that change color with the application of a voltage."

Read more at:

http://www.rdmag.com/news/2015/02/electrochromic-polymers-create-broad-color-palette-sunglasses-windows?et_cid=4406566&et_rid=614174443&type=headline

|

|

|

| Forces exerted by the cells surrounding the gap (dotted blue line) extend away at first, then direct inwards, towards the gap, during contraction of the 'purse-string' cable (red filaments). Image: Mechanobiology Institute, National Univ. of Singapore |

A collaborative study led by scientists from the Mechanobiology Institute (MBI) at the National Univ. of Singapore (NUS) has revealed the mechanical forces that drive epithelial wound healing in the absence of cell supporting environment. This research was published in

Nature Communications.

Sealing the gaps

Skin not only provides an essential protective barrier against foreign materials and pathogens, but it also helps the body retain various fluids and electrolytes. When this barrier is damaged, the consequences can be devastating. Ulcers, bleeding and bacterial infections may result and the chances of these occurring increases the longer wounds remain open.

Fortunately, epithelial cell sheets are self-repairing. The moment the integrity of the barrier is compromised, cellular mechanisms are initiated to close the gap. Cells begin crawling forward, and contractile cables are formed in the cells surrounding the wound to help pull the gap close. For several years, scientists have been learning much about how cells coordinate these processes and repair wounds quickly. In most cases, the healthy skin cells responsible for carrying out wound repair rely on a supporting layer underneath them. This layer comprises sticky proteins, and is known as the extracellular matrix (ECM), which provides support for them to adhere to and crawl over.

However, in cases of chronic or severe wounds, the underlying layers could also be damaged. Surrounding cells could also be unable to replace the ECM proteins. Yet the repair of these gaps, known as non-adherent gaps, does occur, albeit at a slower rate and with an increased likelihood of infection or other complications. So the question remained; how do cells close gaps in protective epithelial barriers where the underlying layers are also damaged or the ECM eroded?

Read more at:

http://www.rdmag.com/news/2015/02/forcing-wounds-close?et_cid=4406566&et_rid=614174443&type=headline

|

|

|

| Advanced manufacturing industries usually boast an advanced supplier base. A case in point is the newly operational vertical bloom caster at TimkenSteel's Faircrest Plant, which supplies premium steel alloys to forging plants. |

Forging is not only an enduring industry, but it is also an advanced industry. Despite Western society's disdain for old and improperly labeled "archaic" metalworking industries (such as foundry or forging), the U.S. forging industry is anything but archaic. In fact, the industry is vibrant, technologically challenging and critical to the country's economic health and defense. Not unlike the ancient workers of bronze or iron, today's workers of steel, aluminum, superalloys and titanium are critical to the current prosperity and future defense of the U.S.

Recognizing that there are many so-called "advanced manufacturing" technologies - e.g., nanotechnology, additive manufacturing, energy systems (batteries, wind power, compressed gas systems, etc.) - we have collaborated to write this article (and those to follow) to illustrate the significance of this critical, enabling metal-forging industry. This is the first in a series of articles we prepared to illustrate the value and necessity of forgings that enable the design and manufacture of high-performance systems in transportation, energy, biomedical and defense, to name but a few. Without the forging industry - an advanced manufacturing industry - the U.S. would be at a tremendous disadvantage in the international marketplace.

Defining Advanced Manufacturing

Along with the current renaissance of manufacturing in America, the label advanced manufacturing has been applied to "new" manufacturing technologies. Considerable discussion amongst the "manufacturing intelligentsia" has offered numerous definitions of advanced manufacturing depending on the viewpoint of the industry.

Read more at: http://www.forgemag.com/articles/84311-north-american-forging-is-advanced-manufacturing

|

Martian colonists could use an innovative new technique to harvest energy from carbon dioxide thanks to research pioneered at Northumbria and Edinburgh Universities.

The technique, which has been proven for the first time by researchers at the two Universities, has been published in the prestigious journal

Nature Communications.

The technique has exciting implications for working in extreme and alien environments, such as outer space, where it could be used to make long-term exploration and colonisation sustainable by using naturally occurring solid carbon dioxide as a resource rather than a waste product. If this could be realised, then future missions to Mars, such as those in the news recently, may not need to be 'one-way' after all.

Dry ice may not be abundant on Earth, but increasing evidence from NASA's Mars Reconnaissance Orbiter (MRO) suggests it may be a naturally occurring resource on Mars as suggested by the seasonal appearance of gullies on the surface of the red planet. If utilised in a Leidenfrost-based engine dry-ice deposits could provide the means to create future power stations on the surface of Mars. journal Nature Communications.

The research proposes a new kind of engine for producing energy based on the Leidenfrost effect - a phenomenon which happens when a liquid comes into near contact with a surface much hotter than its boiling point. This effect is commonly seen in the way water appears to skitter across the surface of a hot pan, but it also applies to solid carbon dioxide, commonly known as dry ice. Blocks of dry ice are able to levitate above hot surfaces protected by a barrier of evaporated gas vapour. Northumbria's research proposes using the vapour created by this effect to power an engine. This is the first time the Leidenfrost effect has been adapted as a way of harvesting energy.

Read more at: https://www.northumbria.ac.uk/about-us/news-events/news/2015/03/breakthrough-in-energy-harvesting-could-power-life-on-mars/

Journal link: http://www.nature.com/ncomms/2015/150303/ncomms7390/full/ncomms7390.html

|

|

|

| Reactive molecular dynamics of Electrochemical Metallization Cell |

Researchers have used an advanced model to simulate in unprecedented detail the workings of "resistance-switching cells" that might replace conventional memory for electronics applications, with the potential to bring faster and higher capacity computer memory while consuming less energy.

These electromechanical "metallization cells" rapidly switch from high resistance to low resistance-a two-state operation that could be used to represent the ones and zeros in the binary code needed to carry out software commands and store information in computers.

Researchers at Purdue Univ. developed a new method to simulate the electrochemical processes that govern the operation with atomistic detail. The researchers used the model to simulate the performance of a type of resistance-switching cells also called conductive bridging cells.

"Despite their importance, the mechanisms that govern their remarkable properties have been poorly understood, limiting our ability to assess the ultimate performance and potential for commercialization," said Alejandro Strachan, a professor of materials engineering at Purdue. "Now, an atomic-level mechanistic understanding of the switching process provides new guidelines for materials optimization."

The resistance-switching cells are being considered as a possible replacement for current non-volatile memory, which is reaching its technological limits and could also be used for logic applications. The conductive bridging cells can switch in a matter of nanoseconds-making them potentially capable of ultra-fast operation-and they are extremely small, possibly allowing for more compact, powerful computer memory, Strachan said.

Findings are detailed in Nature Materials. The paper was authored by Purdue postdoctoral research associate Nicolas Onofrio, graduate student David Guzman and Strachan.

The devices contain two metallic electrodes separated by a dielectric, or insulating material. As a voltage is applied, the active electrode-made of copper in this case-dissolves in the dielectric and the ions start moving toward the inactive electrode. These ions eventually form a conductive filament that connects the two electrodes, reducing the electrical resistance. When the voltage is reversed, the filaments break, switching back to the high-resistance state.

The researchers were able to simulate for the first time what happens at the actual nanoscale size and time regimes of the devices, yielding new information about how the filaments form and break. Findings provide new insights into the electrochemical reactions leading to the formation of the filaments and their breakup, predicting the ultra-fast operation observed in previous experiments with larger devices, with switching as fast as a few nanoseconds.

The emergence of such advanced simulations is making it possible to predict the precise behavior and performance of new devices before they've been constructed, a goal of the Materials Genome Initiative formed in 2011.

Read more at: http://www.rdmag.com/news/2015/03/simulations-provide-new-insight-emerging-nanoelectronic-device?et_cid=4449310&et_rid=614174443&type=cta

Journal link: Atomic origin of ultrafast resistance-switching in nanoscale eletrometallization cells

|

|

|

| Dan Buttry, professor and chair of ASU's Dept. of Chemistry and Biochemistry, examines a battery sample with graduate student Tylan Watkins. Image: Mary Zhu |

Lithium-ion batteries are common in consumer electronics. They are one of the most popular types of rechargeable batteries for portable electronics, with a high energy density, no memory effect and only a slow loss of charge when not in use. Beyond consumer electronics, lithium-ion batteries have also grown in popularity for military, electric vehicle and aerospace applications.

Now, researchers at Arizona State Univ. are exploring new energy storage technology that could give the battery an even longer lifecycle.

Led by Dan Buttry, professor and chair of ASU's Dept. of Chemistry and Biochemistry, the research also involves former undergraduate researcher Jarred Olsen and current graduate student Tylan Watkins. Olsen joined Buttry's group as an undergraduate researcher to work in the ionic liquids area. The work he contributed to this study was performed while he was on an internship at Boulder Ionics working at both Boulder and ASU with Watkins. Olsen is currently a doctoral student at the Univ. of Washington, Seattle.

The research, published in Nature Communications, brings together scientists from Arizona State Univ., Univ. of Colorado at Boulder, Sandia National Laboratories, Boulder Ionics Corporation and Seoul National Univ., Korea.

Prolonging the lifecycle

Room temperature ionic liquids have attracted a great deal of interest in recent years due to their remarkable physicochemical properties, including high thermal stability, wide electrochemical window and low vapor pressure.

"We used a device called a quartz crystal microbalance to measure very tiny mass changes in thin films at the surface of the battery material during charging and discharging," said Buttry. "One of the key features of successful lithium battery materials is that they develop thin films that protect the surface of the battery electrodes, which prolongs the life of the battery. This study documents the development of just such a film in a new type of battery formulation that has many more attractive features than existing commercial lithium batteries."

Buttry added: "The hope is that this new formulation will find its way into commercial use."

The work is part of a larger effort in Buttry's lab that has included funding from the Advanced Research Projects Agency - Energy (ARPA-E) and now from the Army Research Office.

"These were not trivial measurements to make because composite films (meaning a film of the active material in a polymer matrix) are often difficult to use with a quartz crystal microbalance," said Watkins. "Most, if not all, quartz crystal microbalance studies of this sort use very thin films of the active material alone, which means specialty deposition methods must be used. What was cool here is that we were able to make the measurement on a more practical film, something you might realistically see in a commercial battery."

Slides from ThermoScientific: From surface to cell - understanding the Li-ion battery

Read more at: http://www.rdmag.com/news/2015/03/researchers-explore-longer-lifecycle-batteries?et_cid=4449310&et_rid=614174443&type=cta

Journal link:

http://www.nature.com/ncomms/2015/150225/ncomms7230/abs/ncomms7230.html

|

|

|

| This is an artist's rendition of the high pressure thermal conductance experiment in a diamond anvil cell. The flat tips of the diamond anvils are less than half a millimeter in diameter, and the metal film (gray), ruby sphere (red), and pressure medium (blue fluid) are sealed between the diamonds by a metal gasket (solid purple). Image: Alex D. Jerez Roman, Visualization Laboratory, Beckman Institute, Univ. of Illinois |

With more than five times the thermal conductivity of copper, diamond is the ultimate heat spreader. But the slow rate of heat flow into diamond from other materials limits its use in practice. In particular, the physical process controlling heat flow between metals and diamond has remained a mystery to scientists for many years.

By applying extreme pressure in a diamond anvil cell to metal films on diamond, researchers at the Univ. of Illinois at Urbana-Champaign have now determined the physical process dominating this unexplained heat flow, which has implications for understanding and improving heat flow between any two materials.

"Overheating has become a major limiting factor in the performance of high-power RF devices," said David Cahill, a professor and head of the Dept. of Materials Science and Engineering at Illinois. "Modern RF electronics for wireless devices such as satellites and cellphones generate so much heat in a microscopic area that the packing density and performance of RF devices isn't limited by Moore's Law anymore, so much as by how fast we can pull heat away from those devices. For overheating at microscopic length scales, it's not enough to just swap out silicon for diamond; we need a microscopic understanding of how heat enters materials like diamond."

Cahill explained that this work lies more on the fundamental side of thermal physics research, although materials like diamond and silicon carbide are being actively developed as alternative substrates for high powered radio-frequency (RF) devices. "Studies of extremes like metals on diamond at high pressure are valuable because they allow us to test our ideas about what is happening in this complex problem. The experiments we designed let us test and falsify a series of hypotheses, ultimately leading to a better understanding of heat flow between dissimilar materials."

"The simplest way for a phonon to cross an interface is by a two-phonon elastic processes: a phonon comes in, a phonon of the same frequency goes out." explained Greg Hohensee, first author of the paper appearing in Nature Communications. "But metals on diamond are a special case. The diamond is so stiff that it's like banging a pot attached to a rope and expecting the rope to dance. The vibrations stay in the pot, because the rope is not stiff enough to carry such high frequency vibrations. Likewise, you can't make the pot sing by shaking the rope. But somehow, metals on diamond are doing exactly that."

The thermal conductance of an interface determines the rate of heat flow for a given temperature difference between the materials. Typically, the carriers for heat in crystalline materials like diamond are traveling vibrational waves called phonons. A central challenge of thermal physics-and of interfacial thermal conductance, specifically-is that phonons exist over a wide frequency range, and how phonons interact with interfaces and other phonons depends on their frequencies.

Read more at: http://www.rdmag.com/news/2015/03/squeezing-out-new-science-materials-interfaces?et_cid=4450165&et_rid=614174443&type=cta

Journal link:

http://www.nature.com/ncomms/2015/150306/ncomms7578/full/ncomms7578.html

|

|

|

| A small honeycomb structure cloaked the cylinder beneath from being felt |

Physicists are abuzz with possibilities for "metamaterials" that can be designed to have surprising properties.

Tweaking the structure of materials to manipulate things like their appearance is already fairly well-known; the next phase is changing their mechanics.

A major conference is alive with ideas, designs and samples including springy ceramics, unfeelability cloaks and programmable rubber sponges. They could help build spacecraft tiles or even terrain-sensitive shoe soles. "I think this idea of metamaterials is slowly migrating into different areas," said Prof Martin Wegener, from the Karlsruhe Institute of Technology in Germany.

"Originally the excitement was all about electromagnetism - and then it went to totally different areas like thermodynamics and, lately, mechanics."

Prof Wegner also told the BBC that the term "metamaterial" has been applied to all sorts of weird and wonderful designs, without much consistency - but that it usually refers to a case where unusual properties jump out, which would not be expected from the original ingredients.

Now you feel it

Prof Wegener works on cloaking, but his aim is not to make things invisible. He wants to hide them from physical forces, and last year his lab produced a honeycomb-like material that made an object beneath it unfeelable.

This particular metamaterial was a solid lattice that acts like a fluid in certain ways, deflecting pressure around its hidden cargo.

Now the tiny, hidden cylinder was very small in that case (less than 1mm) but related work by Prof Wegener's team was picked up by French physicists and engineers, who showed that a careful pattern of drilled holes could divert damaging earthquake vibrations.

Turning the ground itself into a sort of metamaterial, it seems, might go so far as to protect a power station from a tremor.

Here at the American Physical Society's March Meeting, Prof Wegener presented his latest work - which includes cloaking a hole at the centre of a flat sheet - saying: "It's a design principle. You can apply it to anything you want."

Read more at: http://www.bbc.com/news/science-environment-31725045

|

|

|

| A 3-D rendering of fibrin forming a blood clot, with PolySTAT (in blue) binding strands together. Image: William Walker/Univ. of Washington |

Most military battlefield casualties die before ever reaching a surgical hospital. Of those soldiers who might potentially survive, most die from uncontrolled bleeding.

In some cases, there's not much medics can do-a tourniquet won't stop bleeding from a chest wound, and clotting treatments that require refrigerated or frozen blood products aren't always available in the field.

That's why Univ. of Washington researchers have developed a new injectable polymer that strengthens blood clots, called PolySTAT. Administered in a simple shot, the polymer finds any unseen or internal injuries and starts working immediately.

The new polymer, described in a paper featured in Science Translational Medicine, could become a first line of defense in everything from battlefield injuries to rural car accidents to search and rescue missions deep in the mountains. It has been tested in rats, and researchers say it could reach human trials in five years.

In the initial study with rats, 100% of animals injected with PolySTAT survived a typically-lethal injury to the femoral artery. Only 20% of rats treated with a natural protein that helps blood clot survived.

"Most of the patients who die from bleeding die quickly," said co-author Dr. Nathan White, an assistant professor of emergency medicine who teamed with UW bioengineers and chemical engineers to develop the macromolecule.

"This is something you could potentially put in a syringe inside a backpack and give right away to reduce blood loss and keep people alive long enough to make it to medical care," he said.

The UW team was inspired by factor XIII, a natural protein found in the body that helps strengthen blood clots.

Normally after an injury, platelets in the blood begin to congregate at the wound and form an initial barrier. Then a network of specialized fibers-called fibrin-start weaving themselves throughout the clot to reinforce it.

If that scaffolding can't withstand the pressure of blood pushing against it, the clot breaks apart and the patient keeps bleeding.

Both PolySTAT and factor XIII strengthen clots by binding fibrin strands together and adding "cross-links" that reinforce the latticework of that natural bandage.

"It's like the difference between twisting two ropes together and weaving a net," said co-author Suzie Pun, the UW's Robert J. Rushmer Professor of Bioengineering. "The cross-linked net is much stronger."

But the synthetic PolySTAT offers greater protection against natural enzymes that dissolve blood clots. Those help during the healing process, but they work against doctors trying to keep patients from bleeding to death.

Read more at:

http://www.rdmag.com/news/2015/03/injectable-polymer-could-prevent-bleeding-death?et_cid=4457139&et_rid=614174443&type=cta

Journal article link:

http://stm.sciencemag.org/content/7/277/277ra29

|

|

|

| Rendering of the molecular structure of sodium disilicate glass. Researchers have identified a way to produce glass that is more durable. Image: UCLA Engineering |

Researchers at the Univ. of California, Los Angeles (UCLA) Henry Samueli School of Engineering and Applied Science and the Univ. Pierre et Marie Curie in Paris have identified a method for manufacturing longer-lasting and stronger forms of glass. The research could lead to more durable display screens, fiber-optic cables, windows and other materials, including cement.

Glasses are liquids that are cooled in the manufacturing process to reach a stable "frozen liquid" state. However, as glass ages and is exposed to temperature variations, it continues to flow or "relax," causing it to change shape.

This means that over time, windows and digital screens can deform, eventually becoming unusable. In the case of cement, which has a molecular structure similar to that of glass, relaxation eventually leads to cracking and, in bridges and tall buildings, a loss of structural integrity.

Mathieu Bauchy, an assistant professor of civil and environmental engineering at UCLA, and Matthieu Micoulaut, a professor of materials science at the Univ. Pierre et Marie Curie, have identified optimal conditions for developing more durable glass and cement.

By performing computer simulations to test the molecular dynamics of materials commonly used to make glass, the researchers identified a range of pressures that are best for achieving "thermal reversibility," in which a material will retain the same properties it had when it was produced, even if it has been exposed over time to variations in temperature.

The research was published in Nature Communications.

"The key finding is that if you use specific conditions to form glass-the right pressure and the right composition of the material-you can design reversible glasses that show little or no aging over time," Bauchy said.

Bauchy said the molecular structure of glass is analogous to the metal framework of the Eiffel Tower. Strength and rigidity are partially a result of the angles at which beams and crossbeams connect. The researchers' new process improves the angles at which molecular bonds occur, making the material stronger.

Read more at: http://www.rdmag.com/news/2015/03/process-identified-improving-durability-glass?et_cid=4457139&et_rid=614174443&type=cta

Journal article link:

http://www.nature.com/ncomms/2015/150309/ncomms7398/full/ncomms7398.html

|

|

|

| Color change in an adult male panther chameleon resulting from excitation caused by the presentation of another adult male in its field of vision. (Credit: EpiPhysX science channel/Youtube/Nature Communications) |

Everyone knows that chameleons are the kings of camouflage. But as to the exact process by which these familiar lizards change color to match their environment, no one knew.

Until now.

Previous research suggested that the color change resulted from shifting skin pigments. That's something known to occur in many species of fish, amphibians, and reptiles.

But new research conducted at the University of Geneva in Switzerland suggests that this isn't quite right. When researchers there studied the panther chameleon (Furcifer pardalis), they discovered that the color change is the result of light reflecting off microscopic crystals moving around in the animals' skin. As the crystals change their orientation, so do the wavelengths of light they reflect.

"We discovered that the animal changes its colors via the active tuning of a lattice of nanocrystals," the study's co-authors, physicist Dr. J?r?mie Teyssier and biologist Dr. Suzanne Saenko, said in a written statement. "When the chameleon is calm, the latter are organized into a dense network and reflect the blue wavelengths. In contrast, when excited, it loosens its lattice of nanocrystals, which allows the reflection of other colors, such as yellows or reds."

Next, the researchers hope to study the mechanism that underlies the movement of the nanocrystals. They say this line of research could help engineers develop color-changing materials that could be used for camouflage, Newsweek reported.

The study was published online Mar. 10 in the journal Nature Communications.

Read more at: http://www.huffingtonpost.com/2015/03/11/chameleons-change-color-crystals_n_6847984.html?ncid=newsltushpmg00000003

Journal article link:

http://www.nature.com/ncomms/2015/150302/ncomms7368/full/ncomms7368.html

|

Giant leaps have been made in recent years with 3-D printing. Though most 3-D printed items are made of plastic, more exotic ingredients have included sugar, mashed potatoes, and living cells. A 3-D printer commonly works by depositing a layer of material much like an ordinary printer and then printing out another layer once the material below has solidified. This procedure has a built-in problem: Even small objects take way too long to produce.

An object just several centimeters high can take hours to print. But now scientists at Carbon3D in Redwood City, Calif., and the University of North Carolina at Chapel Hill (UNC) say they can slash printing times by two orders of magnitude. Instead of printing an item step by step and layer by layer, the new technique prints objects in a continuous manner.

A 3-D printer often uses ultraviolet light to harden resins, but oxygen in the air often slows this hardening down. Instead of treating oxygen as an obstacle they had to overcome, the researchers used it to their advantage.

The new 3-D printer starts with a basin filled with a pool of liquid resin. Ultraviolet rays can emerge from beneath through a hole at the bottom of this basin. (Imagine a sink filled with resin where ultraviolet light can shine up from the drain.) In the hole between the basin and ultraviolet rays, where a stopper might fill the hole at the bottom of a sink, is a layer of oxygen-rich liquid tens of micrometers thick. This layer serves as a transparent window for the ultraviolet rays. Solidification cannot occur in this "dead zone."

Read more at: http://spectrum.ieee.org/tech-talk/at-work/innovation/liquid-3d-printing

Journal article link:

http://www.sciencemag.org/content/347/6228/1349

|

|

|

| Photo: Martin Barraud/Getty Images |

Foreign-born talent has fueled many Silicon Valley startups and contributed heavily to U.S. leadership in in science and engineering for decades. But national data shows that just half of science and engineering doctoral recipients who were born overseas end up staying in the U.S. to pursue their post-graduation careers. A new study has teased out several reasons why students choose to stay in the U.S. or go back to their home countries.

The limitations of U.S. immigration policy and H-1B work visas are one of the biggest challenges for foreign students interested in pursuing U.S. careers. That's according to a survey of 166 international graduate students conducted by the Center for Nanotechnology in Society at the University of California, Santa Barbara. Many students who participated in the survey pointed to uncertainty about obtaining permanent resident status after graduation as a major deterrent to both studying in the U.S. and trying to work in the U.S. after graduation. For the study, which appeared in the 11 March 2015 issue of the journal PLOS One, one mechanical engineering student summed up the frustrations of many peers thusly:

The fact that you don't have a green card at the end of your PhD-it's a nightmare. For international students, not having a green card, it impacts the job search, everything. The U.S. is welcoming to graduate students to come and study but there doesn't seem to be a plan for after students graduate. Students settle for jobs that are below them because they work for companies that will provide them with a green card.

But the study also examined how several professional, social and personal factors influenced the decisions of foreign students. The study authors focused on three key decisions: whether to pursue higher education in the home country, whether to stay in the U.S. or return home after graduation, and whether to pursue a career in academia or industry.

One of the strongest predictors of whether a student will stay or leave is whether he or she wants to pursue a career in academia or industry. Students who wanted industry careers had a 90 percent probability of pursuing U.S.-based careers after graduation. By comparison, students who planned to pursue academic careers believed they would receive better treatment from colleagues in their home country. As a result, this group had an 86 percent probability of leaving the U.S. after graduation.

Read more at: http://spectrum.ieee.org/tech-talk/at-work/tech-careers/why-international-engineering-and-science-students-stay-or-go

|

|

|

| Image: U.S. Naval Research Laboratory |

Lately there has been a trend in graphene research to imbue the material with both magnetic and electric properties. But just two years ago, the research world was pretty impressed that a team in Spain was able to make graphene magnetic alone.

Now researchers at the U.S. Naval Research Laboratory (NRL) have gone back to imparting just magnetic properties into graphene, and in so doing may have developed a method that could lead to graphene becoming a new data storage medium capable of a million-fold increase in capacity over today's hard drives.

While previous methods for magnetizing graphene involved putting defects into it or adding chemical groups to it, this new method the NRL researchers developed, which is described in the journal Advanced Materials, is actually a simple and seemingly scalable process. The result is that it can produce large-area magnetic graphene that can be easily patterned.

The production technique starts with putting a layer of graphene over a silicon wafer. The graphene-covered silicon wafer is then placed into cryogenic ammonia that contains a small amount of lithium. This process adds hydrogen to the wafer, which makes it ferromagnetic.

While that is a pretty neat feat, what surprised the researchers was just how evenly the magnetism was spread across the wafer.

Read more at: http://spectrum.ieee.org/nanoclast/semiconductors/materials/graphene-promises-a-millionfold-increase-in-data-storage-capacity

|

|

|

| This figure shows the change in near surface temperatures over time with ocean pipes and without pipes. Image: Lester Kwiatkowski, Ken Caldeira and Katharine Ricke |

To combat global climate change caused by greenhouse gases, alternative energy sources and other types of environmental recourse actions are needed. There are a variety of proposals that involve using vertical ocean pipes to move seawater to the surface from the depths in order to reap different potential climate benefits. A new study from a group of Carnegie scientists determines that these types of pipes could actually increase global warming quite drastically. It is published in Environmental Research Letters.

One proposed strategy-called Ocean Thermal Energy Conversion, or OTEC-involves using the temperature difference between deeper and shallower water to power a heat engine and produce clean electricity. A second proposal is to move carbon from the upper ocean down into the deep, where it wouldn't interact with the atmosphere. Another idea, and the focus of this particular study, proposes that ocean pipes could facilitate direct physical cooling of the surface ocean by replacing warm surface ocean waters with colder, deeper waters.

"Our prediction going into the study was that vertical ocean pipes would effectively cool the Earth and remain effective for many centuries," said Ken Caldeira, one of the three co-authors.

The team, which also included lead author Lester Kwiatkowski as well as Katharine Ricke, configured a model to test this idea and what they found surprised them. The model mimicked the ocean-water movement of ocean pipes if they were applied globally reaching to a depth of about a kilometer (just over half a mile). The model simulated the motion created by an idealized version of ocean pipes, not specific pipes. As such the model does not include real spacing of pipes, nor does it calculate how much energy they would require.

Their simulations showed that while global temperatures could be cooled by ocean pipe systems in the short term, warming would actually start to increase just 50 years after the pipes go into use. Their model showed that vertical movement of ocean water resulted in a decrease of clouds over the ocean and a loss of sea-ice.

Colder air is denser than warm air. Because of this, the air over the ocean surface that has been cooled by water from the depths has a higher atmospheric pressure than the air over land. The cool air over the ocean sinks downward reducing cloud formation over the ocean. Since more of the planet is covered with water than land, this would result in less cloud cover overall, which means that more of the Sun's rays are absorbed by Earth, rather than being reflected back into space by clouds.

Water mixing caused by ocean pipes would also bring sea ice into contact with warmer waters, resulting in melting. What's more, this would further decrease the reflection of the Sun's radiation, which bounces off ice as well as clouds.

After 60 years, the pipes would cause an increase in global temperature of up to 1.2 C (2.2 F). Over several centuries, the pipes put the Earth on a warming trend towards a temperature increase of 8.5 C (15.3 F).

"I cannot envisage any scenario in which a large scale global implementation of ocean pipes would be advisable," Kwiatkowski said. "In fact, our study shows it could exacerbate long-term warming and is therefore highly inadvisable at global scales."

Read more at: http://spectrum.ieee.org/nanoclast/semiconductors/materials/graphene-promises-a-millionfold-increase-in-data-storage-capacity

|

|

|

| Rutgers Univ. chemistry Profs. Martha Greenblatt and Charles Dismukes in a laboratory on the Busch Campus in Piscataway. Photo: Nick Romanenko/Rutgers Univ. |

New research published by Rutgers Univ. chemists has documented significant progress confronting one of the main challenges inhibiting widespread utilization of sustainable power: Creating a cost-effective process to store energy so it can be used later.

"We have developed a compound, Ni5P4 (nickel-5 phosphide-4), that has the potential to replace platinum in two types of electrochemical cells: electrolyzers that make hydrogen by splitting water through hydrogen evolution reaction (HER) powered by electrical energy, and fuel cells that make electricity from combining hydrogen and oxygen," said Rutgers chemistry Prof. Charles Dismukes. "Platinum is the benchmark material for both devices as it has the best conversion efficiency. However, while platinum may be acceptable for making jewelry and low volume specialty applications, it is too expensive for large-scale applications such as energy storage and conversion. Our new HER catalyst, Ni5P4, has the strong potential to overcome this challenge."

Rutgers chemistry Prof. Martha Greenblatt, Dismukes and colleagues published their findings on the patent-pending technology in Energy & Environmental Science.

"Scientists have been working for years to develop low-cost replacements for platinum and other noble metals used in these devices," Greenblatt said. "Ni5P4 is the most promising new material presently available that combines both the energy conversion efficiency of noble metals, yet is much more affordable based on the high natural abundance of its elements-over a million times greater than platinum."

The researchers believe that Ni5P4 should lower the material costs of both electrolyzers and fuel cells, while maintaining the efficiencies of these technologies for electrical conversion. "These devices are two key technological advances that could open the door to renewable fuels produced from sustainable feedstocks-water and sunlight," Dismukes said.

The next step for the research is to test the operating stability and efficiency of the compound over extended time periods in commercial electrolyzers and fuel cells. As these devices have different requirements for operation, independent tests for both will be needed. Rutgers has partnered with Proton OnSite of Wallingford, Conn., a commercial manufacturer of electrolyzers, to test Ni5P4 as an appropriate HER catalyst.

To achieve the overall water splitting process, the HER catalyst cathode will be combined with an oxygen-evolving (OER) catalyst anode. The Rutgers team has previously developed a noble-metal-free OER catalyst-LiCoO2 (lithium cobalt oxide)-that has shown promising performance in preliminary tests at Proton OnSite.

"If used together, these catalysts could eliminate the need for expensive noble metal based electrode materials," Greenblatt said.

Read more at: http://www.rdmag.com/news/2015/03/study-holds-great-promise-advancing-sustainable-energy?et_cid=4473369&et_rid=614174443&type=cta

|

|

|

NIST's new silver nanoparticle reference material is designed for extended shelf life to support environmental health and safety studies.

|

(Nanowerk News) The National Institute of Standards and Technology (NIST) has issued a new

silver nanoparticle reference material to support researchers studying potential environmental, health and safety risks associated with the nanoparticles, which are being incorporated in a growing number of consumer and industrial products for their antimicrobial properties. The new NIST test material is believed to be the first of its kind to stabilize the highly reactive silver particles in a freeze-dried, polymer coated, nanoparticle cake for long-term storage.

| Nanoparticulate silver is a highly effective bactericide. It is, by some estimates, the most widely used nanomaterial in consumer products. These include socks and shoe liners (it combats foot odor), stain-resistant fabrics, coatings for handrails and keyboards, and a plethora of other applications. |

| The explosion of "nanosilver" products has driven a like expansion of research to better understand what happens to the material in the environment. "Silver nanoparticles transform, dissolve and precipitate back into nanoparticles again, combine or react with other materials-our understanding of these processes is limited," says NIST chemist Vince Hackley. "However, in order to study their biological and environmental behavior and fate, one needs to know one is starting with the same material and not some modified or oxidized version. This new reference material targets a broad range of research applications." |

Read more at: http://www.nanowerk.com/nanotechnology-news/newsid=39273.php

Reference link:

https://www-s.nist.gov/srmors/view_report.cfm?srm=8017

|

|

|

| NIST's new silver nanoparticle reference material is designed for extended shelf life to support environmental health and safety studies. |

| (Nanowerk News) Researchers in South Korea have, for the first time, developed a simple technique to produce a two-dimensional nitrogen-containing crystal that has the capacity to be a potential rival to graphene and silicon as semi-conductor materials (Nature Communications, "Nitrogenated holey two-dimensional structures"). |

| Graphene is a two-dimensional (2D) one-atom-thick sheet of carbon crystals that has many extraordinary properties in terms of its strength, electrical and thermal conductivity, and optical transparency. Graphene shows promise for use in nanoelectronics, hydrogen storage, batteries and sensors. Research on graphene in recent years has raised huge interest among scientists about the potential of synthesising other 2D crystals by introducing elements other than carbon into graphene's carbon lattice. The motivation behind this is the possibility this might provide to develop materials that can be used as an active switching element in electronics. |

| The atomic size and structure of nitrogen make it an excellent choice for this purpose because it can fit naturally into a strong network of carbon atoms by creating bonds (sp2) in which electrons are shared by the whole network. |

| Whereas there are many difficulties in the synthesis of graphene, the team of researchers at Ulsan National Institute of Science and Technology (UNIST) and Pohang University of Science and Technology in South Korea synthesized nitrogenated 2D crystals using a simple chemical reaction in liquid phase without using a template. Conventional methods for the formation of 2D crystals require the use of such a template. |

| The researchers verified the structure of the nitrogenated crystal by atomic-resolution scanning tunnelling microscopy imaging and confirmed its semiconducting nature by testing it with a field effect transistor. The unique geometric and electronic structure of the nitrogenated crystals make it potentially suitable for use in electronics, sensors and catalysis. Its successful synthesis using a simple technique may open a new chapter in the cost-effective generation of other 2D materials. |

Read more at: http://www.nanowerk.com/nanotechnology-news/newsid=39347.php

Journal link:

http://www.nature.com/ncomms/2015/150317/ncomms7539/full/ncomms7539.html#contrib-auth

|

|

|

| This transmission electron microscope image shows cellulose nanocrystals, tiny structures derived from renewable sources that might be used to create a new class of biomaterials with many potential applications. The structures have been shown to increase the strength of concrete. (Purdue Life Sciences Microscopy Center) |

WEST LAFAYETTE, Ind. - Cellulose nanocrystals derived from industrial byproducts have been shown to increase the strength of concrete, representing a potential renewable additive to improve the ubiquitous construction material.

The cellulose nanocrystals (CNCs) could be refined from byproducts generated in the paper, bioenergy, agriculture and pulp industries. They are extracted from structures called cellulose microfibrils, which help to give plants and trees their high strength, lightweight and resilience. Now, researchers at Purdue University have demonstrated that the cellulose nanocrystals can increase the tensile strength of concrete by 30 percent.

"This is an abundant, renewable material that can be harvested from low-quality cellulose feedstocks already being produced in various industrial processes," said Pablo Zavattieri, an associate professor in the Lyles School of Civil Engineering.

The cellulose nanocrystals might be used to create a new class of biomaterials with wide-ranging applications, such as strengthening construction materials and automotive components.

Research findings were published in February in the journal Cement and Concrete Composites. The work was conducted by Jason Weiss, Purdue's Jack and Kay Hockema Professor of Civil Engineering and director of the Pankow Materials Laboratory; Robert J. Moon, a researcher from the U.S. Forest Service's Forest Products Laboratory; Jeffrey Youngblood, an associate professor of materials engineering; doctoral student Yizheng Cao; and Zavattieri.

One factor limiting the strength and durability of today's concrete is that not all of the cement particles are hydrated after being mixed, leaving pores and defects that hamper strength and durability.

"So, in essence, we are not using 100 percent of the cement," Zavattieri said.

However, the researchers have discovered that the cellulose nanocrystals increase the hydration of the concrete mixture, allowing more of it to cure and potentially altering the structure of concrete and strengthening it. As a result, less concrete needs to be used.

Read more at: http://www.purdue.edu/newsroom/releases/2015/Q1/natural-nanocrystals-shown-to-strengthen-concrete-.html?

Journal link:

http://www.sciencedirect.com/science/article/pii/S095894651400211X

|

If you used any instruments in the Materials Science Center, Soft Materials Laboratory, or the Wisconsin Center for Applied Microelectronics, please remember to acknowledge MRSEC funded instruments and facilities in any publications (DMR-1121288). This will serve as a metric for how often MRSEC funded instruments are used and will help continue MRSEC support in future years. Thanks! If you have any questions, please contact

Felix Lu

.

|

|

|

Explore the Geology Museum and take a peek into Wisconsin's

deep history!

Explore the Geology Museum and take a peek into Wisconsin's

deep history!

On your visit yo

u can touch rocks from a time when there were volcanoes

in Wisconsin; see corals, jellyfish and other sea creatures that used to

live and swim where we now walk; and stand under the tusks of a mastodon

while imagining yourself in the Ice Age. Also on display at the Geology

Museum are rocks and minerals that glow, a model of a Wisconsin cave,

dinosaurs and meteorites.

Our mineral, rock and fossil collections have the power to educate and

inspire visitors of all ages. Come see for yourself!

|

Science Cafes

What is a science caf??

Science caf?s are live grassroots events held in casual settings like coffeehouses and pubs that are open to everyone, organized locally and feature an engaging conversation with a scientist on a particular topic. Science caf?s have been held in communities across the globe for years.

To learn more, visit sciencecafes.org

Who should attend?

Everyone! Science caf?s are free and open to the public. No prior scientific knowledge is needed, so anybody can participate.

What would I do at a science caf??

Science caf?s start with a presentation by a scientist or group of scientists about the evening's topic. Then the conversation about the topic begins. A science caf? is not a formal lecture-audience members are encouraged to ask questions and participate in the discussion.

|

|

Student tour groups of your facility

|

Industrial facilities tours?

Are you interested in showing off your facility to interested student groups? Do you want to increase exposure of what your company does to encourage higher application rates and get student interns? Hosting a tour might be a good start! Please contact

Felix Lu or

Erin Gill to initiate this!

|

|

Using our campus facilities

|