COMPLIMENTARY PIKES PEAK SHUTTLE SERVICE

BEGINS MAY 24

Pikes Peak - America's Mountain provides a complimentary shuttle system to ease the parking disruption caused by construction of the new Pikes Peak Summit Complex. Visitors should be prepared to pay the normal, seasonal rates for utilizing the Pikes Peak Highway; however, there is no additional charge for the shuttle or for parking in the shuttle lots. Pikes Peak - America's Mountain provides a complimentary shuttle system to ease the parking disruption caused by construction of the new Pikes Peak Summit Complex. Visitors should be prepared to pay the normal, seasonal rates for utilizing the Pikes Peak Highway; however, there is no additional charge for the shuttle or for parking in the shuttle lots.

The shuttle is based on parking capacity in the summit lot; operating hours and lot operation will vary daily. Limited parking spots at the summit of Pikes Peak will still be available during construction; however, priority for these spots will be given to certain travelers:

- Vehicles carrying disabled passengers

- Vehicles carrying small children in car seats

Other visitors not meeting these exemptions will likely be required to use the shuttle. Guests visiting during peak visitation hours - 9 a.m. to 3 p.m., please plan longer wait times for shuttles due to the increased visitation demand. There is no impact on fishermen or others who are using the highway to enjoy the many other recreational opportunities provided by Pikes Peak - America's Mountain.

T

o ensure prompt shuttle availability, once the shuttles have departed the parking lot, they will not make any stops until reaching the summit. The same is true for the return trip. There are plenty of pull-off opportunities to take advantage of before you get to the shuttle lot.

Other Important Information:

- Minimum of ½ tank of fuel needed

- Use low gears downhill

- Turn off air conditioner

- Plan a minimum of 2 to 3 hours round trip

- Drink lots of water during and after your trip

- Sorry, no pets or bicycles on shuttle

If you have questions about the shuttle, please call 719-385-PEAK.

|

BUSY SUMMER SEASON AHEAD AT THE SUMMIT*

With the spring snowmelt upon us, work on the Pikes Peak Summit Complex is gearing up for a busy summer construction season.

Crews working on the summit complex this summer will install either waterproofing or weather-resistant barriers to keep moisture out and be working on insulation. "Workers will have a 45- to 60-day window to place 430 precast pieces of below-grade, load-bearing members, composite veneer sandwich panels comprised of 8 inches of structural concrete, 8.5 inches of expanded polystyrene insulation and 3 inches of non-structural concrete veneer," says Jack Glavan with Pikes Peak - America's Mountain, who manages the Pikes Peak Summit Complex project for the City of Colorado Springs.

Portions of the main floor and roof plazas will consist of precast double-tees; the rest of the flooring will be slab on grade. The plaza roof, when incorporating structural inverted tee-beams and double tees, in addition to a topping slab, insulation drain boards and wearing slab, will measure 73.5 inches. All told, wall systems carry an insulation R-Value of 60 and the roof an insulation R-Value of 90. R-Value is a measure of insulation's ability to resist heat traveling through it. The higher the R-Value, the better the thermal performance of the insulation. The R-Values required at the summit of Pikes Peak are much higher than what is normal for our Colorado climate due to the extreme temperatures at the summit.

During periods of extreme wind, the 1-inch-plus-thick glazing will be protected from flying grit and gravel using roll-down metal shutters in the dining area and entry vestibule. The exception is the all-glazed elevation, whose 4-foot-high by 8-foot-wide members collectively are too wide and tall to allow for a shutter system. As a result, the project team is performing tests that will subject sample sections to projectiles propelled by 270 mph winds.

*Information extracted from ENR Engineering News-Record

|

MORE TO SEE, MORE TO DO, MORE TO LEARN

A variety of design elements and multimedia tools customized for the Pikes Peak experience will providing interesting opportunities for sharing and storytelling once the new Pikes Peak Summit Complex is completed and open in 2020.

- Rail Panels - On the roof terrace and inside the lobby, rail panels provide general information about the mountain's geology, history and current use.

- Touchscreens - An interactive touchscreen wall lets visitors explore the aspects they're most interested in.

- Trails - Elevated walking and hiking trails with interpretive elements are safe and accessible and reduce environmental impact.

- Mobile App - A mobile app will provide a guided experience in the visitor center and on the summit grounds. Pikes Peak - America's Mountain will utlize the TravelStory App, a GPS-based mobile application that provides information as visitors drive up the mountain of 20 key points of interest. TravelStorys is a hands-free, location-aware app sharing authentic stories by locally sourced, podcast-style audio guides. Less like an app and more like a compass, TravelStorys works offline and inside a pocket - so visitors can focus on their surroundings instead of their device. Download the app for free on the App Store or Google Play to experience self-guided audio tours.

In 2012 Story Clark (http://www.storyclark.net/bio.htm), a renowned land conservationist, founded TravelStorys as a tool to showcase the value of open spaces so that we might preserve those places for future generations. The scope of TravelStorys has expanded to include historic locations, scenic byways, river walks, paddling tours and many more.

|

FROM DOWN HERE TO UP THERE -- LOCAL COMPANY FABRICATES STRUCTURES IN COLORADO PRINGS PLANT FOR TRANSPORT TO THE SUMMIT ONCE WEATHER ALLOWS.

Stresscon Corporation is one of the contractors working on the Pikes Peak Summit Complex. Founded in 1967, Stresscon designs, fabricates, and erects structural and architectural precast concrete structures for projects throughout Colorado and the Rocky Mountain region.

A certified producer member of the Precast/ Prestressed Concrete Institute, Stresscon is recognized among the leading precast companies in the United States that specialize in institutional and commercial applications. Stresscon houses a 68-acre production facility in southeast Colorado Springs and an additional plant in Thornton, Colorado.

Throughout this past winter and spring, Stresscon has been busy at its production facility in Colorado Springs producing the 418 precast pieces that will be used on the Pikes Peak Summit Complex. In addition, there will be 64 precast pieces used on the

High-Altitude Research Laboratory (funded by the U.S. Army)

. Each day there can be more than 250 employees working on projects including the Pikes Peak Summit Complex at the 68-acre Stresscon production facility. Product lines include architectural and structural building elements: prestressed double tees, prestressed beams, columns, hollow-core plank, insulated and non-insulated wall panels, etc. The plant produces more than 400 cubic yards of concrete in

multiple types and colors each day

. With 5 to 6 lifts that handle 80,000 pounds each, they are able to run 6 to 10 custom jobs at any given time. "It's all made for the specific job and designed for the specific needs. It is always custom made for the project's exact specification, no two jobs are the same," said Don Palmer, Vice President of Stresscon Corporation. Throughout this past winter and spring, Stresscon has been busy at its production facility in Colorado Springs producing the 418 precast pieces that will be used on the Pikes Peak Summit Complex. In addition, there will be 64 precast pieces used on the

High-Altitude Research Laboratory (funded by the U.S. Army)

. Each day there can be more than 250 employees working on projects including the Pikes Peak Summit Complex at the 68-acre Stresscon production facility. Product lines include architectural and structural building elements: prestressed double tees, prestressed beams, columns, hollow-core plank, insulated and non-insulated wall panels, etc. The plant produces more than 400 cubic yards of concrete in

multiple types and colors each day

. With 5 to 6 lifts that handle 80,000 pounds each, they are able to run 6 to 10 custom jobs at any given time. "It's all made for the specific job and designed for the specific needs. It is always custom made for the project's exact specification, no two jobs are the same," said Don Palmer, Vice President of Stresscon Corporation.

For the most efficient structural system, the exterior wall panels should be loadbearing. Loadbearing panels are structural components that transfer gravitational or vertical loads from other elements and contribute to the strength and stability of a structure. Loadbearing elements include solid wall panels as well as composite and non-composite insulated panels, all of which may contain blockouts for doors and windows. For the most efficient structural system, the exterior wall panels should be loadbearing. Loadbearing panels are structural components that transfer gravitational or vertical loads from other elements and contribute to the strength and stability of a structure. Loadbearing elements include solid wall panels as well as composite and non-composite insulated panels, all of which may contain blockouts for doors and windows.

Prestressed concrete used on the Pikes Peak Summit Complex provides superior crack control and long-term performance over traditional reinforcement techniques. With the addition of prestressing steel, transverse steel may be minimized and often eliminated, making the production process faster and easier.

Insulated wall panels will be used on the Summit Complex as they have been shown to hold superior strengths and energy absorption characteristics. This has been revealed through recent, full scale testing and blast simulations with end results that place precast wall systems high above traditional building methods.

During a recent tour of the Stresscon facility, staff from the City of Colorado Springs had the opportunity to see first-hand production of the columns and insulated walls. The prefabricated walls and columns will be store

d until the weather allows for 10 semi-trucks to make the daily morning trip up the mountain to deliver the precast pieces to the summit. These trips will occur before the Pikes Peak Highway opens for visitors. During a recent tour of the Stresscon facility, staff from the City of Colorado Springs had the opportunity to see first-hand production of the columns and insulated walls. The prefabricated walls and columns will be store

d until the weather allows for 10 semi-trucks to make the daily morning trip up the mountain to deliver the precast pieces to the summit. These trips will occur before the Pikes Peak Highway opens for visitors.

|

|

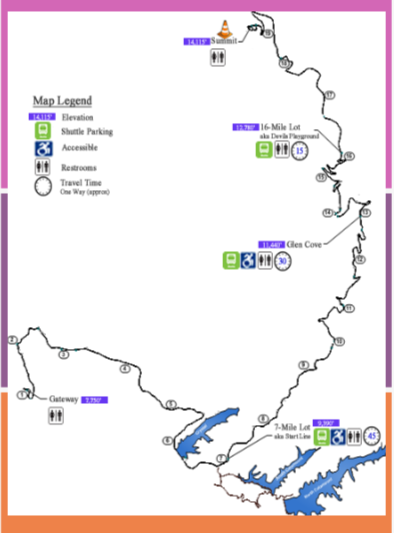

SHUTTLE PICK-UP LOCATIONS AND TIMES

Visitors who use the shuttle will drive part way up the Pikes Peak Highway to one of three parking lots before taking the shuttle to the summit. Shuttles will arrive at the shuttle parking lots approximately every 5 to 10 minutes:

- 16-Mile Lot: The shortest shuttle ride is from the 16-mile lot (Devils Playground) and will take approximately 15 minutes to drive up and 20 minutes to drive down.

- 13-Mile Lot: The 13-mile lot (Glen Cove) will take approximately 25 minutes to go up and 35 minutes to come down by shuttle.

- 7-Mile lot: The 7-mile lot (Pikes Peak International Hill Club start line) will take approximately 30 minutes to go up and 45 minutes to come down by shuttle.

- Persons with a disability, who would like to use the shuttle, should ask the Gateway Ranger for assistance at the time of entry.

|

UPCOMING (SUMMER 2019) CONSTRUCTION ACTIVITIES

- The contractor and its crews are currently mobilizing equipment to the summit, installing Best Management Practices (BMPs), and removing snow and ice

- Now through July - crews will install a building mockup for materials testing (illustration below)

- May - Concrete and precast will be start being placed - forms, reinforcing, and embeds will be installed prior to placing concrete for foundations

- May through September - Permatrak systems for Central and North Permatrak will be installed

- July - Structural Steel installation will start (frame and detail roof)

- End of August/through September - Vapor barrier, rebar/mesh, and MEP systems (Mechanical, Electrical and Plumbing) for the Plaza, Main, and Lower Levels will be installed

Illustration of a mockup, a section of the building to test constructability and performance of materials that will be used on the building overall.

|

|

KEY 2019 MILESTONE DATES

- Foundations - Early Summer 2019

- Structural Steel - Early Summer 2019

- Concrete Slab Sequence - Early Summer 2019 - Mid-October 2019

- Exteriors - Early Summer 2019 - Late Fall 2019

- Precast - Summer 2019

- Dry in and Winter-Tight - Fall 2019

Project Completion: Late 2020

|

A CAMPAIGN FOR THE PIKES PEAK SUMMIT COMPLEX

Help Build the New Pikes Peak Summit Complex

Ways to Contribute:

Support the project at the Pikes Peak Visitor Center Gift Shops (Crystal Reservoir, Glen Cove and at the Summit)

- Purchase a Pikes Peak Summit Book

- "Give-a-Buck" -- add $1 to any purchase at the gift shops

-

Take a dip and

donate at any Dip Jar

in the gift shops

|

FOLLOW THE PROJECT - SIGN-UP FOR

NEW HEIGHTS NEWSLETTER

Send an email to

and request to be added to the

e-newsletter distribution list.

|

|

PARTNERS WORK TOGETHER

TO MAKE PROJECT REALTY

- U.S. Forest Service

- National Park Service

- State Historic Preservation Offices and tribal representatives

- City of Colorado Springs, Pikes Peak - America's Mountain

- The Broadmoor Pikes Peak Cog Railway

- The U.S. Army High Altitude Laboratory

- Colorado Springs Utilities

- US Army Research Institute of Environmental Medicine

- Citizens, supporters and community leaders

|

|

COG RAILWAY DECOMMISSIONS AND REMOVES OLD TRAINS, MAKING WAY FOR RENOVATION AND NEW RAIL

Decommissioning of the old Cog Railway trains and equipment took place in March, including gifting two trains and memorabilia to the City of Manitou Springs for use in and around the City as well as use for a Cog Railway museum that may be built at some point in the future. Removing the trains went smoothly. Similarly, taking inventory of the many pieces of equipment and spare parts collected over the years and finding good homes for them was a labor of love for the Cog Railway staff.

In late March, renovation of the Cog Railway got underway in earnest with the general contractor and employees beginning demolition at the depot complex.

Existing track was demolished, beginning in the depot complex and working toward the summit. Deliveries of new friction rail (the two outside rails) and ballast also began in April. Staging for this is in the Cog Railway parking lot and is moving up the mountain in anticipation of the construction period after demolition is complete. CLICK HERE for more information.

|

|

PIKES PEAK MARATHON FACT

The Pikes Peak Marathon is the third oldest marathon in the country. The event starts at the base of Pikes Peak, in Manitou Springs, and runners climb more than 7,800 feet to the summit. Due to the hazards and difficulty of the race, only 800 runners can compete each year. This year the Pikes Peak Marathon is scheduled for Sunday, August 25. CLICK HERE for more information.

|

FEATURES OF THE PIKES PEAK SUMMIT COMPLEX

-

Sustainability

The Summit Visitor Center is poised to live in balance with the unique environmental conditions at the summit. Using sustainable building practices, the visitor center will offer some of the same experiences by the mountain's first visitors more than 200 years ago, while also enhancing the visitor experience both inside and out.

-

Economic Benefits

Today, nearly 750,000 visitors arrive at our mountain's summit each year, contributing roughly $30 million to the local economy. At any given time, as many as 600 visitors may be exploring the summit. Nearly 50,000 visitors hike the Barr Trail to the summit each year.

-

Accessibility (ADA Compliance)

The peak will be accessible to all, regardless of age or mobility. Visitors have the option to hike to the summit, arrive by bicycle or vehicle traveling the 19-mile Pikes Peak Highway, or ride the Cog Railway, currently being reconstructed. The new Pikes Peak Summit Visitor Center and summit will be ADA accessible.

-

Outdoor Amenities

New dining facilities, an outdoor dining terrace, and an expanded gift shop entice visitors to browse our collection of books on area history, wildlife, and the environment; pause for refreshments at the café or at an outdoor dining area; and take photographs of the unequalled vistas. Enhanced dining and retail increase earned revenue to support ongoing operations and invite

repeat visits.

|

|

|

|