|

Wind, flood, and fuel: Harvey and Irma

|

|

|

|

Hurricane Harvey's flood waters triggered a spill of 461,000 gallons of gasoline from two storage tanks along the Houston Ship Channel.

|

|

"The 2017 Atlantic hurricane season has climbed the ranks of the all-time most active seasons on record, thanks to a frenetic stretch of long-lived, destructive hurricanes from mid-August through early October," according to The Weather Channel. "The 2017 Atlantic hurricane season has climbed the ranks of the all-time most active seasons on record, thanks to a frenetic stretch of long-lived, destructive hurricanes from mid-August through early October," according to The Weather Channel.

Hurricanes Harvey and Irma caused extraordinary damage in Texas, Puerto Rico, and southeastern U.S. states.

Loss of human life and property due to these events is overwhelming and tragic. Petroleum fuels storage operations are also affected and contribute to the losses. Here are links to reports, articles, and information about the impact of these disastrous events:

|

|

|

SP001 revision comments due October 27

The STI/SPFA AST Inspection Standards Review Committee is soliciting public comment through October 27, 2017, on revisions to

SP001, Standard for the Inspection of Aboveground Storage Tanks and

SP031, Standard for Repair of Shop-Fabricated Aboveground Tanks for Storage of Flammable and Combustible Liquids.

For more information, contact Dana Schmidt at

[email protected]. Comment deadline is October 27. Publication of the new editions of SP001 and SP031 is anticipated in early 2018.

|

|

STI's free AST maintenance brochure

All storage tank systems, both underground (UST) and aboveground (AST), constructed of any material, and storing nearly any product--gasoline, diesel, residential and commercial heating oils, aviation jet fuel--are susceptible to damage if water is allowed to accumulate. The potential for damage applies not only to the tank, but also to the entire storage system.

STI recently published a brochure, "Inspect your tanks, maintain your tanks, reduce your risk," containing information about keeping water out of AST systems. A similar brochure focused on UST systems was published in spring of 2016. In total, these brochures were sent to all registered owners of STI tanks since 1991.

"These documents are part of our continuing efforts to educate tank owners,

operators, regulators, and consumers about the effects of water on fuel and in fuel storage tank systems," said Wayne Geyer, Executive Vice President of STI-SPFA.

Both brochures are free for reproduction and distribution at

www.steeltank.com, on the tab "Fuel Storage Tank System Maintenance." If you have difficulties with the download, contact

the Editor.

|

|

STI revises R051 CP testing requirements

Thanks to a committee of dedicated industry experts, STI recently published a revised version of

R051, Recommended Practice for Testing Cathodic Protection of sti-P3 tanks.

Changes to R051 include a sample form for the CP tester; new drawings and figures to better illustrate how to conduct a CP test; a new definitions section; and information on the care and maintenance of CP testing equipment.

R051 is based on application of sound engineering principles and the combined experience of the revision committee members. It's compiled of data from tank owners, manufacturers, regulatory authorities, and cathodic protection testers.

CP testers and others looking for basic knowledge about how to test sti-P3 tanks will find it an easy-to-follow guide.

R051 and all other STI documents are available

from our website Store.

STI extends appreciation to these members

of the R051 Revision Committee:

Coby Hayes, Chair

JL Houston Co. Inc. |

Mike Asma (Alternate)

VA DEQ |

Matthew J. Cutshall

Sheetz, Inc. |

Kevin Henderson

K. Henderson Consulting, LLC |

Mike Hill

Mass Tank Inspection |

Andrew J. Koenig

Enerfab, Inc. |

Steve Nagy

Tait Environmental |

Michael Phelps

NC DENR |

Bob Pickens

AT&T Services, Inc. |

Stephen Pollock

VA DEQ |

Michael Pomes

US EPA |

Brian Pottebaum

R&A Risk Professionals/PMMIC |

Rick Rogers

UST Corrosion Management |

Tim Sievert

Advanced Corrosion Control |

William Simpson

PCA Engineering, Inc. |

Eric M. Swaisgood

Speedway LLC |

Ed Ward

SC Fuels |

|

|

|

What happened to this tank?

What do you think happened to this tank? Email your comments to the Editor and we'll publish the best answer in the next issue of Tank Talk.

|

|

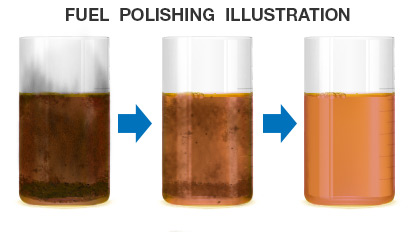

Fuel polishing: getting rid of bugs

With th

e incr

eased occurrence of microbial

contamination in fuel storage tanks since the advent of biofuels, "fuel polishing" is a rapidly-growing service business. Fuel polishing is the technical cleaning process used to remove or filter microbial contamination from oil and hydrocarbon fuel in storage. With th

e incr

eased occurrence of microbial

contamination in fuel storage tanks since the advent of biofuels, "fuel polishing" is a rapidly-growing service business. Fuel polishing is the technical cleaning process used to remove or filter microbial contamination from oil and hydrocarbon fuel in storage.

Ron F. Sickels, PhD--known as "The Fuel Doctor"--has 25 years of experience specializing in fuel and tank quality, as a mechanical, chemical and environmental engineer.

Tank Talk asked Dr. Sickels, currently Vice President of Purification Services for Relevant Solutions, LLC, to answer a few questions about fuel polishing.

|

|

The nation's infrastructure gets only a D+ grade

"Every four years, the American Society of Civil Engineers' Report Card for America's Infrastructure depicts the condition and performance of American infrastructure in the familiar form of a school report card--assigning letter grades based on the physical condition and needed investments for improvement..."

That's the introduction to ASCE's 2017 Infrastructure Report Card website. The report is comprehensive and dense with information, by state and by infrastructure sector.

|

|

Ice-cold tank inspections in Antarctica

"Inspection of storage tanks in Antarctica is not something that can be done on a moment's notice. It requires preparation for some of the harshest weather on the planet..."

|

STI's tank repair standard

SP131 "most complete and current"

Many state and federal regulators look to STI's standards and recommended practices for definitive storage tank criteria.

Recently, a state regulator called STI-SPFA to ask if he could include an article about STI's SP131 tank repair standard in a newsletter. "I've read all the tank repair standards and STI's SP131 is the most complete and current," he said

By way of review, STI's SP131 standard covers the inspection, repair, and modification of an atmospheric-type, shop-fabricated, carbon and/or stainless steel underground storage tank. It applies to tanks storing stable liquids at atmospheric pressure.

SP131 covers tanks built to a nationally-recognized standard for underground storage tanks. It may be used for the repair of other tanks at the discretion of the tank owner. It applies to tanks that are installed and also to tanks that have been temporarily removed to achieve a repair.

|

|

27 year old UST is clean as a whistle

Here's another demonstration that steel storage tanks last virtually forever, if they're properly inspected and maintained.

This sti-P3 tank was recently pulled and found to be in pristine condition after 27 years underground.

|

|

| Back to top |

|

|

|

"Weird, but in a good way" department

This just in from inhabitat.com: "

The answer to our global plastic catastrophe may be in sight. Spanish researchers have discovered that the wax worm, a caterpillar known for munching on the wax within beehives, is able to

devour and biodegrade

polyethylene plastic, converting it into a form of alcohol found in antifreeze."

|

|

| |

|

|

|

|

|

|

| "One of the best websites in the industry." --Site survey |

|

STI/SPFA Education and Certification Programs

Click links below for information and registration

Nov.15-16, Lexington KY

December 4-8,

Baltimore MD

|

|