|

|

|

Kevin Cornell

Vice President |

Kevin here.

Much is happening at SSR since my last message to you in May. One major advancement in our production line is the addition of the

Planet 25 Plus Stainless Steel machine for coil processing, straightening and shaping. I'll let Kyle Hayes our Branch Manager share a few details and connect you with the video.

There are projects worthy of mention that Kyle and Michael can describe, and I will brief you on our certification in the Concrete Steel Reinforcing Institute Stainless Steel Fabrication Certification Program.

I hope to see you in person at World of Concrete 2020 in Vegas and the Precast Show 2020 in Fort Worth. I will be watching for you.

Let me know if you plan to attend by visiting our events page on Facebook or mailing me at

[email protected]. I am there to discuss projects, share technical information, and have a little fun with friends.

|

|

Celebrating one year in the CRSI Fabrication Certification Program

Salit Specialty Rebar is complying with ANSI/CRSI-IPG4.1 and passing its audits

The Concrete Reinforcing Steel Institute (CRSI) Standard Practice for Stainless Steel Reinforcing Bar Fabrication Facilities (ANSI/CRSI-IPG4.1) defines quality processes for fabrication of stainless steel reinforcing bars. Processes encompass the development and use of a fabrication quality manual, proper personnel training, inspection criteria, handling and storage, fabrication, and shipping to job sites.

Performance requirements have been added where rated load capacities are assigned to a reinforcement support, based on the ability of the support to meet minimum requirements of load test, impact test, water absorption criteria and concrete consolidation test.

The American National Standards Institute (ANSI) accredited the Concrete Reinforcing Steel Institute (CRSI) as a Standards Development Organization (SDO) in April 2013. The scope of CRSI's standards activities includes the development and maintenance of consensus standards for design, detailing, fabrication, placement, and construction of assemblies consisting of steel reinforcement and associated products used in concrete and masonry construction.

|

|

|

CRSI list of stainless steel reinforcing bar fabrication facilities

|

Over the past 12 months, SSR has welcomed and passed several audits to maintain its certification with the Concrete Reinforcing Steel Institute.

|

Planet 25 Plus Stainless Steel added to SSR's production line

|

|

|

Kyle Hayes

Branch Manager |

The MEP

Planet 25 Plus Stainless Steel machine for coil processing, straightening and shaping is producing preformed rebar for clients in the USA and Canada. The machine can bend rebar in many shapes other than a pretzel.

MEP Group is a leading company in the rebar equipment manufacturing and resistance welding technology. the company has been working with customers since 1967.

MEP Group produced a video that speaks volumes about the capabilities of the machine. If you are specifying stainless with a twist, contact me at

716-299-1990 or mail me at [email protected].

|

|

Brooklyn Sanitation District Brooklyn 3 Garage

Salit Specialty Rebar supplied 1,

060 tons of

316LN stainless steel rebar that has

a lower chromium content, higher nickel than 304, and a 2% moly addition. The latter enhances the corrosion resistance found in harsh environments, especially halogens (chlorides). It offers superior resistance to pitting or crevice corrosion failures typical to high salt of coastal areas and urban areas where there is heavy use of deicing salts. The alloy is austenitic providing excellent formability, weldability, and cryogenic ductility. In addition, this grade has higher creep strength; higher stress ruptures strength and improved tensile strength as compared to 304 type alloys.

The garage is the second of this type supplied by SSR in New York City, using 316LN.

Stainless steel rebar is typically used in sanitation garages for reinforcement in the loading and tipping floors. The stainless steel rebar is added protection against the affect of water and salt on concrete structures. The project is expected to be completed in 2021.

Owner:

Contractor:

SSR Customer:

Stainless Steel Rebar Supplied:

|

NYC Department of Sanitation

MPCC Corp.

Brooklyn Rebar

1,060 tons of 316LN |

Information Sources:

|

From the southern end of the Pea Island National Wildlife Refuge over the Pamlico Sound into Rodanthe, N.C.

North Carolina

Highway

12 (

NC 12

), from the southern portion of the Pea Island National Wildlife Refuge to northern Rodanthe including a section known as the 11 S-curves, is susceptible to breaches caused by storms. including Hurricane Irene in 2011 and Hurricane Sandy in 2012. To remedy the situation,

the N.C. Department of Transportation approved construction of a structure to elevate this

portion of N.C. 12 onto a 2.4-mile bridge - known as a jug handle.

|

|

|

Michael Cornell

Proj Mgr/Sales |

Salit Specialty Rebar

is supplying 1,850 tons of Grade Enduramet 32 / XM-28 (UNS24100)

stainless steel for the deck, barrier wall, piles, and caps.

Enduramet 32 / XM-28 is a high-manganese, low-nickel, nitrogen strengthened austenitic stainless steel. By means of solid solution strengthening, the nitrogen provides significantly higher yield and tensile strength as annealed without adversely affecting ductility, corrosion resistance or non-magnetic properties. Because of its low magnetic permeability, it may also be considered for concrete rebar applications in close proximity to sensitive electronic devices and magnetic resonance medical equipment.

The Rodanthe Bridge ensures safe and reliable passage for travelers, as well as better traffic flow among the Outer Banks communities, beaches, and protected areas.

An innovative approach to construction was Flatiron's Advancing Rail System, which combines the ability to straddle the newly built bridge structure and to leap frog temporary work sections. The rail system and application of precast concrete elements will help Flatiron complete the bridge earlier than NCDOT estimates.

View the Dare County video (2:35) that describes an update of the project to August 8, 2019 and shows the unique rail system. CLICK HERE

Owner:

SSR Customer:

Contractor:

Stainless Steel Rebar Supplied:

|

North Carolina Department of Transportation

Harris Rebar North Carolina

Flatiron Construction

1,850 tons of

Grade Enduramet

32 / XM-28 (UNS24100)

|

|

VA I-64 South Side /High Rise Bridge

|

|

|

Michael Cornell

Proj Mgr/Sales |

Improvement of the Interstate 64 ( 1-64) corridor from

1-464 to 1-664/264 include the High Rise Bridge to address insufficient transportation capacity and correct roadway and bridge deficiencies throughout the corridor. The bridge adds capacity to a key evacuation route. Upon completion, the existing bridge will carry

1-64 east traffic (toward 1-264/Bower's Hill), while the new bridge being constructed immediately to the south, will carry 1-64 west traffic toward Virginia Beach.

Salit Specialty Rebar is supplying 3,200 tons of Grade 2304 (UNS32304) for the deck, barrier wall, and caps.before completion in 2021.

This alloy is a lean duplex stainless steel that has a microstructure consisting of austenite and ferrite phases. This duplex microstructure and the chemical composition of 2304 Duplex stainless results in an excellent combination of strength and corrosion resistance. 2304 Duplex stainless possesses good resistance to general corrosion in many acid environments, chloride stress corrosion cracking, pitting, and crevice corrosion.

Watch (2:12) Project Director Mike Prezioso summarize the project

CLICK HERE

Owner:

SSR Customer:

Contractor:

Stainless Steel Rebar Supplied:

|

Virginia Department of Transportation

Harris Rebar North Carolina

Granite-Parsons-Corman

3,200 tons of

G

rade 2304 (UNS32304)

|

|

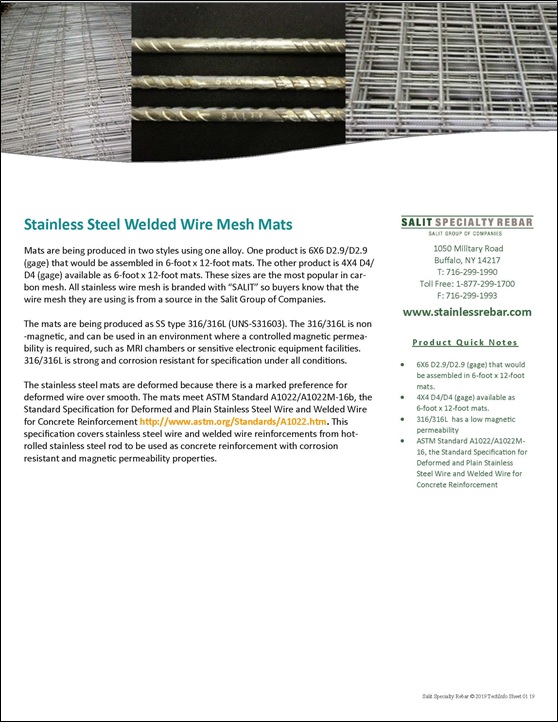

Stainless Steel Welded Wire Mesh Mats

Mats are being produced in two styles using one alloy. One product is 6X6 D2.9/D2.9 (gage) that would be assembled in 6-foot x 12-foot mats. The other product is 4X4 D4/D4 (gage) available as 6-foot x 12-foot mats. These sizes are the most popular in carbon mesh. All stainless wire mesh is branded with "SALIT" so buyers know that the wire mesh they are using is from a source in the Salit Group of Companies. Mats are being produced in two styles using one alloy. One product is 6X6 D2.9/D2.9 (gage) that would be assembled in 6-foot x 12-foot mats. The other product is 4X4 D4/D4 (gage) available as 6-foot x 12-foot mats. These sizes are the most popular in carbon mesh. All stainless wire mesh is branded with "SALIT" so buyers know that the wire mesh they are using is from a source in the Salit Group of Companies.

The mats are being produced as SS type 316/316L (UNS-S31603)

.

The 316/316L is non-magnetic, and can be used in an environment where a controlled magnetic permeability is required, such as MRI chambers or sensitive electronic equipment facilities. 316/316L is strong and corrosion resistant for specification under all conditions.

|

World of Concrete February 4

The Precast Show March 5

Kevin, Rick, and Michael will be at the show to help you understand the many applications of stainless steel rebar and wire mesh reinforcing. Take time to visit with us at N3007.

Kevin, Rick, and Michael will be at at Booth 327.

|

Bookmark SSR's website for technical info

The Salit Specialty Rebar website builds a case for specifying stainless steel reinforcement through archived technical information, listing of SSR services and products, and providing links to engineering services for designers who may wish to consult with SSR's specialists during the planning stage of a project.

The site archives photos and videos highlighting SSR's fabrication equipment, facilities, projects, and people who work with clients daily.

|

LIKE SSR's Facebook page to help build a network of stainless steel reinforcement specialists

Salit Specialty Rebar is building a community of followers by encouraging clients, past clients, prospects, Salit family staff, and people interested in the stainless steel reinforcement industry to LIKE the SSR Facebook page. Salit Specialty Rebar is building a community of followers by encouraging clients, past clients, prospects, Salit family staff, and people interested in the stainless steel reinforcement industry to LIKE the SSR Facebook page.

Social media sites have a growing role in business, related to current events that distribute 10 to 30 second news releases in copy, photos and video that keep followers informed.

When a person LIKES the SSR page, they automatically opt into following the page. This means that SSR posts will be seen in their feed and SSR will be listed in their 'LIKED' directory.

|

|

SSR Company LinkedIn Page reserved for technical papers and professional development

SSR launched a company page on LinkedIn to help promote the Salit Specialty Rebar and Salit Steel brands. By routinely populating the site with technical and professional opinions about stainless steel rebar and mesh, the site strengthens the positioning of all divisions of Salit Steel.

CLICK HERE to follow the SSR network on LinkedIn

|

|

SSR ships products throughout the USA and Canada

1050 Military Road, Buffalo NY

|

|

| |

|

About Salit Specialty Rebar

Thank you for buying our products and enlisting our services. We appreciate your business.

With stainless steel rebar, mesh and mats in our product line, we look for the support of our clients to help build our brand as North America's specialist for stainless steel reinforcement.

Our corporate vision is one of leadership, innovation and consistently exceeding expectations. This vision is backed by extensive experience in the industry. As with all members of the Salit Steel family, we pride ourselves in providing unparalleled customer service.

Team SSR

Kevin Cornell, Vice President Salit Specialty Rebar Sales

716-299-1990

Michael Cornell,

Project Manager/Sales

Rick Huza, Director, Business Development

Kyle Hayes, Branch Manager

Shari Otis, Office Administrator

Salit Specialty Rebar

1050 Military Road

Buffalo, NY

14217

|

|

|

|

Social Media

Connect with SSR on its social media sites to receive timely news about the company and its products and services, along with industry news.

Please visit and LIKE our Facebook page and FOLLOW our LinkedIn Company Page. These are ways to stay informed about SSR's stainless steel reinforcing products and services.

|

|