|

|

|

|

|

SidePlate's

® Role in Resiliency

By Ryan Smith, P.E., S.E.

Western Regional Business Manager

SidePlate Systems, Inc.

SidePlate partners with hundreds of design and construction teams each year. We experience firsthand the process our partners use to select the best design for a particular project.

Until now, these discussions generally result in the most economical solution that meets function and code requirements. I am happy to say that we are seeing that changing with Resiliency becoming part of the discussion.

More frequent hurricanes and earthquakes are causing building owners to realize that the true cost of these events goes

beyond initial destruction and human safety to include clean-up, lost usage of the asset and the direct repair cost to return the building back to its original function. This realization is bringing focus to the importance of resilient-based designs that can more quickly and economically recover from natural events. SidePlate has been working over the last decade to develop connections which delay the onset of inelastic deformation and the progressive damage commonly found with conventional steel connections. Repairing panel zone deformation usually presents the greatest challenge and expense to bringing a steel moment frame back to full functionality following an event. While our clients have been utilizing SidePlate technology to provide more resilient structures for decades, the advantages of these benefits are becoming more important.

SidePlate is proud to be a founding member and supporter of the United States Resiliency Council (USRC). The USRC has developed a 5-star rating system that ranks the building's repair and recovery cost to return a building to its full function following a catastrophic event. Moving forward, SidePlate will be working to incorporate Resiliency information into our designs, documentation, company website and communications. We urge our client partners to familiarize themselves with the wealth of great information on the USRC website

(USRC.org) and

begin discussions within your company on how you can leverage Resiliency to differentiate your business and better serve our customers. SidePlate is committed to continue pushing the envelope through our research and development to offer the best connection technology available to create more resilient steel frame buildings.

|

|

|

Visit SidePlate at these Events

(click for more info)

|

|

|

|

|

|

|

Airports Taking Off with SidePlate

The advantages that SidePlate delivers to healthcare, government, commercial and school projects are well known. But the airport construction market has really been taking off for us recently. We've often been involved in specialty areas of airports (air traffic control towers, etc.),

but the economic benefits of SidePlate's improved fit-up, larger range of beam and columns sizes, and field-bolted connections have gotten the attention of design and construction teams on new airport terminal projects across the country.

One of the first to utilize a SidePlate design is the new Salt Lake City (SLC) airport expansion currently under construction. SidePlate's increased stiffness and wider range of available member sizes enabled the design team to provide an economical solution to the project's challenging geometry. Shortly after working on the this project, the new San Francisco airport team utilized a SidePlate design to solve similar challenges. And since then even more airport terminal projects including LAX; Portland, OR; Missoula, MT; and South Padre Island, TX are moving forward with SidePlate designs. Next time you fly, be sure to look up...it's becoming more likely that you'll see SidePlate in action.

|

|

Innovation Update

SidePlate Systems continually pushes the envelope of steel connection technology through in-depth analysis and testing. We periodically get questions on this research so we are pleased to announce that we will be sharing our work with you in an

"Innovation Update" in future newsletters. The information will be written by Behzad Rafezy, PhD, SidePlate's Director of Research and Development. We hope you find the column interesting and useful.

Effective Throat of Flare Bevel Welds at the Corners of HSS in SidePlate Connections

Behzad Rafezy, PhD

Director of Research and Development

SidePlate Systems, Inc

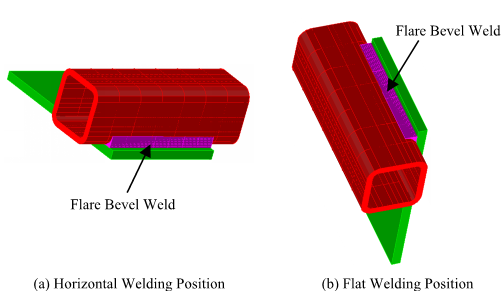

Ongoing research and development that strengthens structural steel designs is a core value at SidePlate. Recently we conducted experimental and numerical studies to investigate the effective throat size of flare-bevel groove welds in different welding positions. A flare-bevel is a weld made in the groove between a plate and a curved surface such as the rounded corners of cold formed hollow structural sections (HSS). Several HSS-to-plate flare bevel welds (not filled flush) with different underfill weld sizes were carefully performed in both horizontal and flat welding positions. After careful inspection and measurement, multiple cross-sections were cut and tested.

The test results showed that the effective throat size reported in AISC Specification Table J2.2 is overly conservative. It was also concluded that the horizontal welding position provides approximately 10% more throat size and capacity than the flat welding position which is opposite of the initial impressions. Test results were used to verify the validity of the numerical study. Various finite element models were created and analyzed to extend the conclusions of the study to different geometric parameters.

It was determined that a flare-bevel groove weld can confidently be applied at the corners of cold formed hollow structural sections with a large safety margin and not necessarily be filled flush.

Although the study was initiated to calculate the effective throat size of the welds connecting the side plates to the walls of HSS columns in the SidePlate® connections, the results are applicable to any similar situations.

Figure 1. Flare Bevel Welding Positions

(a) Horizontal Welding Position (b) Flat Welding Position

Figure 2.

|

|

Season's Greetings!

The SidePlate Team sincerely thanks you for your friendship and business this past year and wishes you and your families Happy Holidays and a safe and prosperous 2018.

|

|

This e-mail was sent by:

SidePlate

25909 Pala, Suite 200

Mission Viejo, CA 92691

(949) 238-8900

|

|

|

|