|

Key Elements in Achieving Accurate Local and Global Alignments

Having a proven ultra-accurate machine platform that is mechanically and thermally stable, with no cantilevered parts, is a baseline to achieve accurate device placement. In addition, the accurate alignment of device fiducials is required to achieve micron level accuracies. Many other key features are required for accurate final placement.

Alignment Software Local and global vision alignment is used for nested substrates and feature alignment. The software must allow the user to align die relative to substrate fiducials, die edges, or features of previously placed die. The alignment of the laser chip to photo diode or a lens to a VCSEL are common photonic examples. Another example is the alignment of critical die such as MMICs and beam lead diodes. This capability ensures repeatability and precise alignment of optical and microwave devices. Programmable Multi-color Lighting Multi-colored lighting is required to successfully vision process a wide range of materials. Tri color; red, green and blue programmable lighting provides the capability for processing challenging alignment surfaces, such as gold traces on alumina. Lighting intensity must be programmable and include both ring and collimated lights for a complete lighting solution. It must be possible to individually program optimal light settings for each die and substrate fiducial alignment.

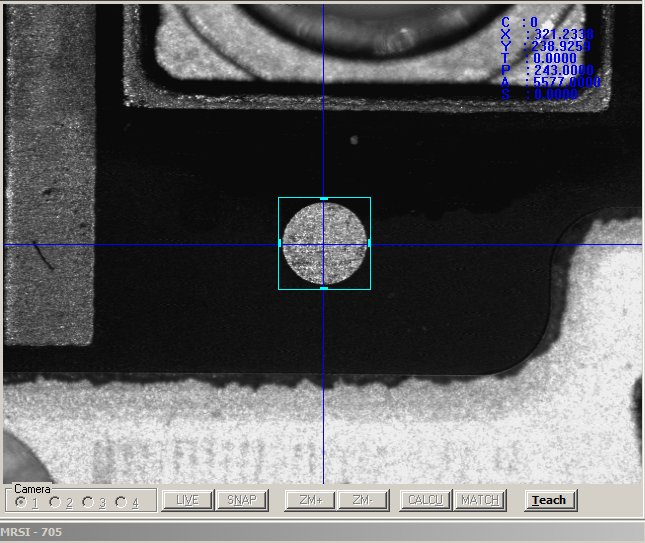

Advanced Machine Vision

Advanced vision must rapidly perform robust substrate fiducial alignment regardless of material contrast and detect and orient die over a full 360°. Both pattern recognition and boundary trace tools provide a complete solution to locate the die center, edges, or application-critical features. This enables fast, error-free processing of complex assemblies.

Optics and Camera System

The optics and camera system must include multiple magnifications for both upward and downward facing cameras. The upward-facing camera is used for processing flip chip devices and other components with bottom features and bumps. High resolution cameras ensure a quality vision image for processing.

If you have similar challenges, give our application experts a call.

|